You can download and print this document: YM Efficiency factsheet PDF419.39 KB

First response

AMSA carried out its compliance role to inspect and detain the vessel once it arrived in port and supplied its Challenger Jet to track missing containers. Contractors hired by the ship’s insurers collaborated with NSW Roads and Maritime Services to carry out the initial shoreline clean-up operation.

Over 1000 tonnes of debris was cleared from around 400 kilometres of coastline, including plastics, wooden furniture, tyres and paper products.

A thorough search for the lost containers using a side scan sonar and a remotely operated underwater vehicle (ROUV) was used to match the containers with the ship’s manifest. Five containers have been recovered and there are 16 containers yet to be found.

Removing the containers

Removal and disposal of the 60 containers, is scheduled to start in March 2020. The salvage operation is expected to take a month to complete, subject to weather conditions.

Ardent Oceania is contracted to recover the containers and associated debris from the seabed using the offshore support vessel, MV Pride, which is designed for offshore salvage and construction operations.

MV Pride is 130 metres long and offers 2000 square metres of deck space and 6000 tonnes of cargo carrying capacity. MV Pride is equipped with a 250-tonne active heave-compensating subsea crane and a 35-tonne auxiliary crane. The MV Pride contains two ROUV hangars with a dedicated ROUV control room.

An ROUV will support the operation to:

- manage crane strops and wires

- cut containers to separate them

- create water egress holes

- pick up loose debris.

A crane will lift each container into a custom-fabricated metal basket, which has small mesh to minimise spillage. On surfacing, the basket and container will be lifted to drain then the container removed by crane for storage on the ship’s deck.

If a container cannot be lifted into the basket, the crane will load debris and container pieces into the basket using a hydraulic grab. Loose debris will be stored in enclosed bins and a small vessel will retrieve any debris that may escape. A crane grab aided by the ROUV will clear the site and the ROUV will carry out surveys to ensure debris is cleared.

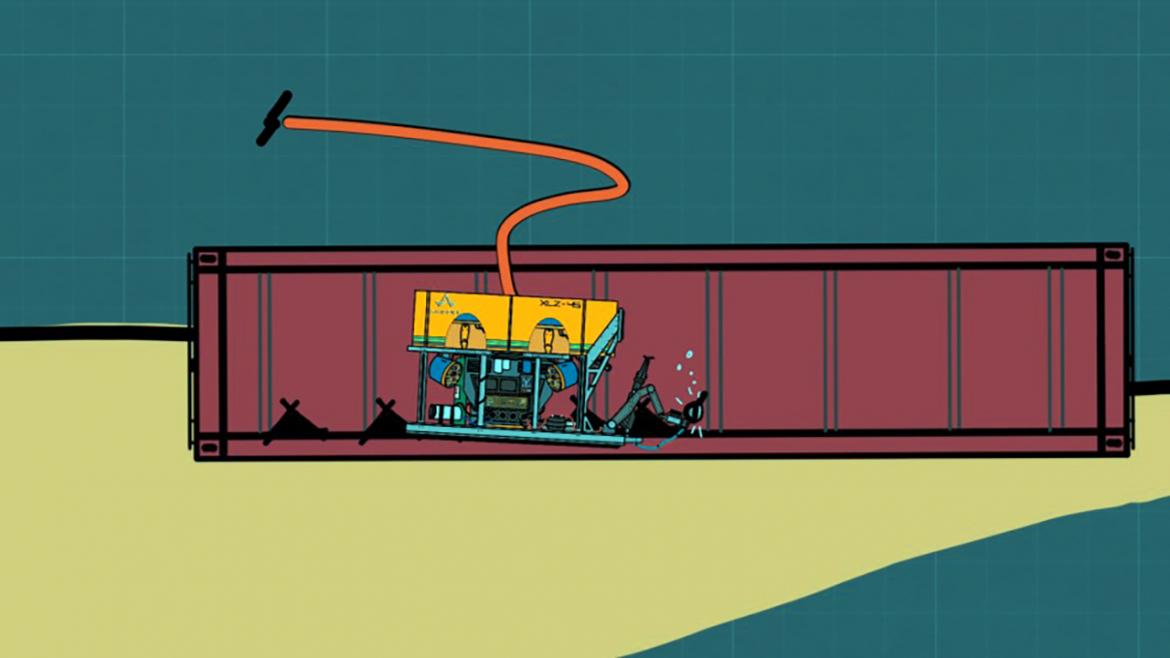

ROUV cuts drain holes in the container with hydraulic saw.

ROUV cuts drain holes in the container with hydraulic saw.

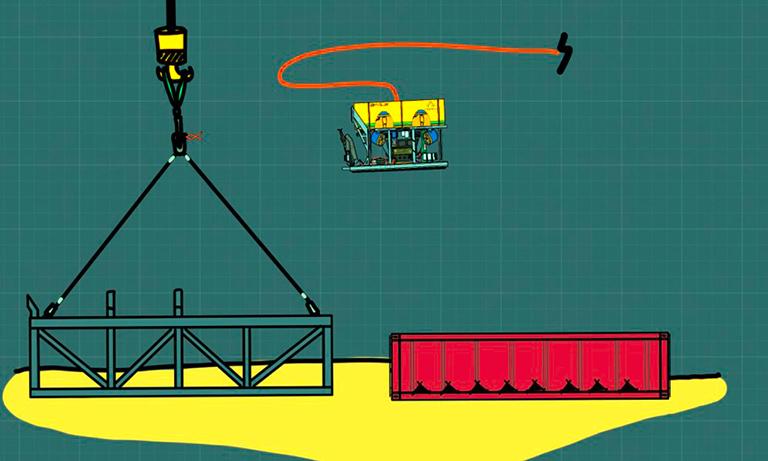

Recovery frame lands on seabed near container.

Recovery frame lands on seabed near container.

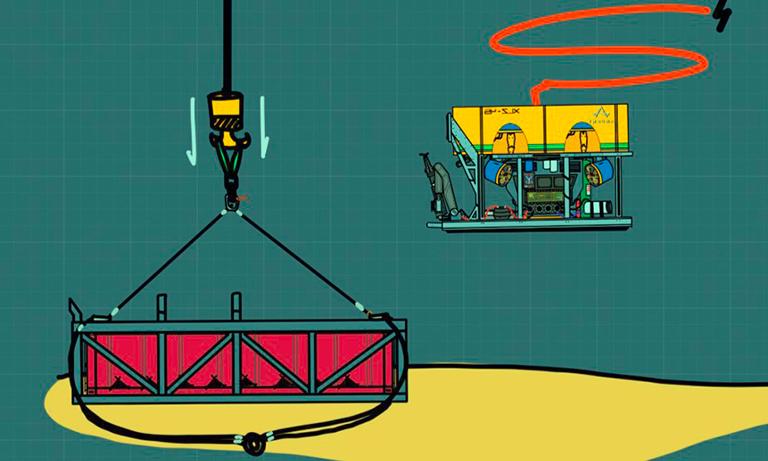

Crane inserts container into frame.

Crane inserts container into frame.

Storing the debris

Port of Newcastle is hosting a receiving area where all recovered waste will be managed. The area will be bunded to prevent debris and pollution from entering port waters. Waste will then be classified, stored, transported and disposed of according to NSW Environmental Protection Authority Waste Classification Guidelines.

Cost recovery

The ship’s owners Yang Ming are responsible for retrieving containers and meeting the costs of retrieving containers – the principle being that the polluter pays. Yang Ming’s failure to fulfil their obligations to retrieve the containers has meant that AMSA has stepped in to start the recovery operation. AMSA intends to recover all costs associated with the clean-up from Yang Ming and their insurers Britannia P&I.

If you have any questions about the YM Efficiency operation please email us at operationrecovery@amsa.gov.au or phone us at 1800 324 861.