In this edition

- Correct and incorrect use of conditions

- Inclining experiment methods

- NSCV C7A safety equipment requirements

- LPG Installation case study

- B extended operations

- N & C flag requirements

- Testing and servicing of fire suppression equipment

- Have your say: NSCV C1 consultation

- National Law review

- Construction barge safety campaign

- Exemption 6 has been updated

Correct and incorrect use of conditions

Conditions are used to impose additional requirements on duty holders. They cannot be used to avoid compliance with a requirement of the law. This is only permitted by exemption.

Correct use of conditions

Conditions can be used to require a duty holder to do additional things. For example, AMSA could impose a condition requiring a master to check engine oil each morning (if we believed it was necessary and correct to do so).

Checking the oil is not a “standard” requirement of the law. Marine Order 503 and the standards do not explicitly require the master to check the engine oil each morning. Nonetheless, if a condition is imposed on the certificate, the master would be required to meet this condition (see section 38 of the National Law).

Incorrect use of conditions

A condition on a certificate cannot be used to “overrule” or contradict the requirements and conditions set out in the National Law.

For example, the National Law Marine Orders may require a vessel to carry a life raft. A condition cannot be used to overrule this requirement. A condition such as "life raft not required to be onboard provided master only operates in D waters” would not have the desired effect. It is not an exemption.

Examples of correct conditions

- Opening between engine room and steering compartment at Frame 37 to be closed watertight during 1D operations

- Recommended Condition: Vessel operations limited to within 30NM radius of safe haven and able to return to safe haven from any point in 2 hours. Reason: Vessel fitted with single anchoring system.

Examples of incorrect conditions

- Vessel to operate in 1D until in service life raft returned to vessel

- Vessel to carry life-saving equipment (Life jackets and life buoys) appropriate to the number of crew onboard.

- Fuel tank to be removed and inspected at or before next renewal survey in September 2023

If you come across a vessel that does not comply with the law, for example because the life raft is not onboard or because they have not completed the surveys required by the Law; then your duties as a surveyor are to communicate the deficiencies to the owner on an AMSA 586, and work with the owner to ensure the issue is rectified. If the owner needs to operate with exemptions, flexibility is provided through Exemption 6 and Exemption 7. Where appropriate, the owner may also apply for a specific exemption.

Inclining experiment methods

The National Law permits the use of equivalent and alternate solutions for meeting the standards. This may permit use of alternate incline methods, on a case-by-case basis. AMSA has for example allowed some smaller vessels to apply the ASTM F3052-14 and SNAME Technical Bulletin 9-1 methods for air inclinings.

An article entitled Scaling the Wall: Inclining Experiment Analysis on Vessels with Chines, Hull Discontinuities or Asymmetry was recently published by Richard Dunworth, Naval Architect, Department of Defence, in the November 2021 issue of The Australian Naval Architect.

This article introduces and discusses the merits of a KN based inclining method that may deliver more accurate inclining results for asymmetrical hull forms and vessels where waterplane area changes during inclining, such as RIB’s.

Surveyors who wish to apply this method for vessels, that are difficult to incline in a traditional manner, or any other non-conventional method, such as air inclining, can apply for an equivalent means of compliance using AMSA form 649.

If you are considering applying for an equivalent solution, please ensure you are familiar with the method you intend to apply and can demonstrate the method will be at least as effective as the solution it replaces. For example, with the KN method:

- KN values must be available and accurate for small intervals of heel. 5-degree intervals such as traditionally used in a stability assessment are not sufficient.

- Procedures must ensure the vessel is free to heel and will not hang on lines, touch bottom or similar. Noting the method does not appear to have a mechanism to identify these types of issues, particularly because results may be non-linear as waterplane area changes.

NSCV C7A safety equipment requirements

Marine Order 503 requires all vessels to comply with NSCV C7A for safety equipment. This means new, existing and transitional vessels.

The latest amendment of NSCV C7A commenced on 1 January 2018 and includes Annex I which outlines the phased arrangements for existing vessels to meet with regards to updating safety equipment. Annex I includes timeframes starting from the next periodic or renewal survey after 1 January 2018, during which time the update in specific equipment must be carried out. There are also deadline dates should no periodic or renewal surveys occur beforehand.

At the time of writing this article, all deadline dates have now passed, except for the requirements for stowage of liferafts (within 12 months of the next out of water survey or 1 January 2023). The following is a summary of some of the major items that surveyors must be looking for during periodic and renewal surveys. The list below is not exhaustive, and AMSA recommends surveyors familiarise themselves with all the requirements of NSCV C7A if they haven’t done so already. NSCV C7 Equipment guidance notices are also available on the AMSA website.

IMPORTANT: Only lifesaving equipment that falls under NSCV C7A requires updating. Anchoring, navigation, and communication equipment are not required to be updated to the NSCV standards on existing vessels.

| NSCV C7A Clause | Description | Requirement |

| 4.3.1.3 | Signage | Stowage locations for safety equipment shall be marked. The signage shall indicate the type of equipment and the quantity if more than one unit is stowed there. The signage should use symbols conforming to IMO Res A.760(18). |

| 4.5.3 | Liferaft stowage | For Class 1 vessels only - Means shall be provided to ensure that the stowage positions of liferafts, the launching devices (where fixed launching devices are used), and the areas of water into which the liferafts will be deployed shall be sufficiently illuminated |

| 4.5.4 | Liferaft signage | Posters, signs, or operating instructions shall be provided on, or in the vicinity of liferafts and their launching controls and shall— a) illustrate the purpose of controls and the procedures for operating the appliance and give relevant instructions or warnings; and b) be easily seen under emergency lighting conditions. NOTE: Symbols used should conform to IMO Resolution A.760(18) Symbols Related to Life-saving Appliances and Arrangements. |

| 4.6.4 | Illumination of dinghy stowage and launching areas | Means shall be provided to ensure that the stowage positions of dinghies and the areas of water into which the dinghies will be deployed shall be sufficiently illuminated |

| 4.7.3 | Illumination of buoyant appliance stowage areas | Means shall be provided to ensure that the stowage positions of buoyant appliances are sufficiently illuminated. |

| 4.8.2 | Lifebuoy stowage | A lifebuoy shall be stowed so that it— b) is readily accessible to crew or passengers; and |

| 4.9.2 | Lifejacket stowage | Lifejackets shall be stowed in clearly marked, easily located, and readily accessible stowage areas. The stowage areas shall be dry and protected from weather and excessive heat. |

| 4.9.3 | Lifejacket signage | Written and pictorial instructions to be provided adjacent to lifejacket stowage area |

| 4.10.1 | Pyrotechnic stowage | Pyrotechnic and smoke signals shall be stowed in a buoyant watertight container, fitted with a handle or lanyard. The container shall be clearly and permanently marked as to its contents. On Class 1 and Class 2 vessels the container shall be readily accessible to the crew. On Class 3 vessels the container shall be mounted in a float free position and be readily accessible. |

| 5.3, tables 2, 3 and 4 | Dinghy replacement | Except for certain Class 3C vessels, a dinghy is not permitted to be used as an alternative to an inflatable liferaft. For Class 3C vessels <25m, a dinghy may continue to be used as an alternative to an inflatable liferaft provided it meets the requirements of NSCV C7A Annex C within 12 months from next periodic or renewal survey, or within 24 months from 1 January 2018, whichever occurs first. Where the existing dinghy being used in place of a liferaft is due for replacement, it shall be replaced by an inflatable liferaft. |

| 5.3 table 2 | Open reversible liferafts | Class 1 vessels that carry buoyant appliances (Carley Floats) and operate in areas where it may be unsafe for persons to be immersed in water (e.g., Water temperatures below 15 deg or dangerous wildlife) must replace their Carley floats with Open Reversible Liferafts (ORLs). Vessels that opt to carry buoyant appliances must have a risk assessment included in their SMS that justifies the use of buoyant appliances in lieu of ORLs. |

| 5.3 table 2 | Buoyant appliances and lifebuoys | A vessel shall carry the kind and quantity of buoyant appliances and lifebuoys mentioned in Table 2 |

| 5.3, tables 2, 3 and 4 | Number of lifejackets | A vessel must carry lifejackets for 100% complement. In particular, 1E vessels that were permitted to carry fewer lifejackets under the USL Code must now carry 100% complement. |

| F2.6 | Painter on Carley floats | A buoyant appliance shall be fitted with a painter that shall be of sufficient length to allow deployment of the buoyant appliance from its maximum possible height and have a breaking strength of 10 kN. |

| H3.2 | Medical equipment and supplies | Equipment supplies shall be in accordance with H3.2. NOTE: This includes the kind, quantity, scale and standard of medical equipment and supplies. NOTE: GES 2015/01 may also apply for C, D and E water vessels where the owner/master has done a risk assessment. |

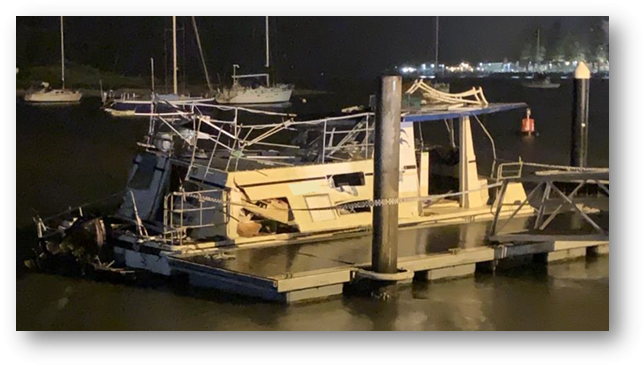

LPG Installation case study

In June last year an explosion occurred on board a houseboat when the owner attempted to light a gas-powered stove via a piezo ignition switch. The explosion caused catastrophic damage to the vessel structure & fittings and both people on board were hospitalised with burn related injuries.

AMSA inspected the 9.9m vessel following the incident and found that major structural damage had occurred to the superstructure, windows, doors, hatches, compartments, fittings and fixtures. The join of fibreglass between the hull and superstructure was cracked and had delaminated away from the hull in the area surrounding the lower cabin. The carpet and curtains were singed, whilst the galley and dining area floor had delaminated. The dining table had also been flipped upside down.

The vessel had a fixed gas system installed which was certified to supply a cooktop, refrigerator, and instantaneous hot water system. Two 8.5kg LPG cylinders were located on the upper deck during inspection, one was connected to the fixed gas system.

Two gas connections were located in the galley during inspection. One supplied the gas cooktop while the other was not connected to an appliance. There was no gas fuelled refrigerator on the vessel. The hot water system was connected to one of the LPG cylinders on the upper deck and was not supplied by the fixed gas system. A valve and connection linked to the fixed gas system was also located externally aft of the vessel, but it was not connected to a hot water system.

Following the incident AMSA engaged a gasfitter to inspect the fixed gas system. At the time of inspection, the gasfitter found the system was not compliant with the requirements of Gas Supply (Consumer Safety) Regulation 2012 because:

- Gas appliances as indicated on the compliance plate were not installed

- Where appliances weren’t fitted, the connection points were not sufficiently capped to prevent a gas leak

- A gas detector was not on board

Following a pressure test of the system, the unused gas connection in the galley was found to be leaking when tested in the off position. The connection and valve located externally was also found to be leaking. The components of the external connection were made from a half-inch kinko nut and olive compression fitting. These fittings are manufactured for use in water copper pipe systems and are not compliant with gas system requirements.

The gasfitters report stated that it is likely the LPG leak from the disconnected gas fridge isolation valve in the galley would have contributed to the presence and accumulation of explosive vapour within the vessel.

AMSA concluded that:

- Propane gas was most likely the cause of a flammable gas air mixture within the vessel

- A faulty gas isolation valve leaking through an open outlet within the kitchen cabinetry was likely the source of uncontrolled gas escape

- The source of ignition was almost certain to be the piezo ignition switch on the gas cooktop which was operated by the owner in the moment before the explosion

AMSA reminds surveyors of the periodic survey requirements listed in Table 9 of SAGM Part 2. Surveyors should look for signs of alterations, modifications, deterioration and disconnections when inspecting the condition of LPG systems. Verification of compliance certificates/plates for installed gas equipment is also required under Table 9. In accordance with section 6 of the National Law, gas systems must also comply with the applicable state or territory gas safety regulator requirements. A licensed gasfitter should inspect the system if there are any concerns.

B extended operations

NSCV Part B defines B extended operations as:

...for use beyond 200 nm from the baseline of any of the following but in waters to the outer limit of the EEZ:

(I) the Australian mainland;

(ii) the Tasmanian mainland;

(iii) a recognized island

Additionally, the definitions of 1B extended, 2B extended and 3B extended state that the vessel must comply with the NSCV requirements for use in operational area unlimited domestic operations.

The phrase operational area unlimited domestic operations is of crucial importance as this is the definition used for Operational Area Category A.

What are the implications?

A vessel that is used for operations in B extended area is required to meet the NSCV requirements for class 1A, 2A or 3A vessels as applicable where specific B extended requirements are not defined.

The NSCV contains several significant changes between Operational Area Category B and Operational Area Category A.

A summary of the changes that may need to be addressed is given in the table below (current for NSCV as at March 2022)

| NSCV Part | Application for Operational Area B extended vessels |

| C1 | The accommodation level must be AL72+ Some changes apply in Chapter 6 requirements may apply |

| C3 | Vessel must comply with robust operation and LR SSC G5 service area restriction, this may require reassessment of the vessels structure. |

| C4 | Some class 1 vessels will have an increase in fire risk category: e.g., Class 1 vessels with 13 – 36 berthed passengers and Class 1 vessels with 37 – 200 day passengers will increase from FRCIII to FRCIV |

| C5A | Class 1 vessels must comply with Marine Order MO12 irrespective of length. Class 2 vessels greater than 35m and 500GT must comply with MO12 Bilge pump requirements change. |

| C5B | The capacity of emergency power supply in class 2 and 3 vessels increases from 2 to 12 hours |

| C5C | No changes |

| C5D | No changes |

| C6A | 5B stability criteria is not applicable to catamarans All vessels must apply the severe wind and weather criteria in Annex H |

| C6B | Class 1 vessels must meet SOLAS Chapter II-1 |

| C6C | No changes |

| C7A | Vessels must comply with Marine Order MO25 and Marine Order MO11 |

| C7B | Vessels must comply with Marine Order MO27 |

| C7C | Vessels >24m must comply with Marine Order MO27 |

| C7D | No changes |

These changes are applicable for new vessels. Some, if not all, will apply to transitional vessels. It is strongly recommended that a gap analysis is carried out early in the process to identify any areas that require upgrading when any vessel is considering operating in operational area B extended.

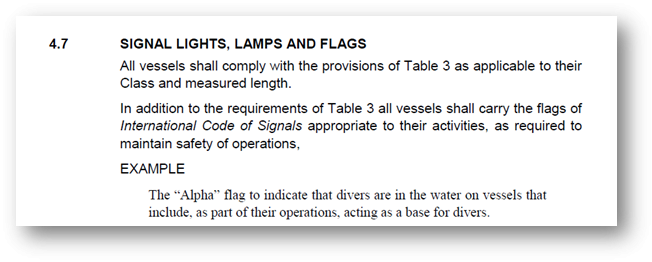

N & C flag requirements

Recently AMSA has become aware of some confusion surrounding the requirements for the provision of signal flags under the NSCV.

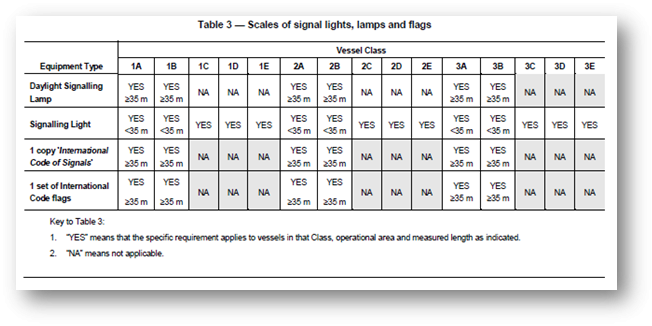

The requirement for signal flags is enlivened under NSCV C7B section 4.7 and table 3 (see below)

l

l

There is no requirement in table 3 to carry a full set of international code flags for vessels in operational areas C, D and E. Section 4.7 only requires carriage of the specific flags which are appropriate to maintain safe operations (which is upon the operator to decide based on their operational risk assessments in the vessel SMS). The example given being the “A” flag for diving operations or the “H” flag for pilotage operations

It is often thought that the “N” & “C” flags are required as part of section 4.7. There is no direct requirement under the NSCV for the carriage of these flags. The USL code Section 13 did require the “N” & “C” flags for vessels in service category class 1C and 2C and all vessels in service areas A & B. The NSCV does not require the carriage of the “N” & “C” flags for vessels in C, D or E service areas.

Testing and servicing of fire suppression equipment

Written by the Fire Protection Industry (ODS & SGG) Board

The Fire Protection Industry (ODS & SGG) Board (FPIB) is encouraging domestic commercial vessel owners and operators to prioritise the regular testing and servicing of fixed fire suppression equipment, irrespective of when a vessel is due to be surveyed under Marine Order 503.

For owners and operators of vessels in low or medium survey frequency it might seem convenient or cost-effective to coordinate testing or servicing of fire suppression equipment when the vessel is due to be surveyed.

However, these owners and operators should not take unnecessary risks by putting off routine testing and servicing of fixed fire suppression systems and/or portable extinguishers as these are safety-critical devices and it is vital they function properly in the event of a fire to preserve both life and property.

While some vessel owners and operators may view this maintenance as an unnecessary expense because they consider the possibility of a fire to be low, a lack of testing and servicing can lead to much higher costs down the track.

Owners and operators may not be aware that the chemical agent inside the fire suppression system on their vessel has a higher chance of unintentionally discharging the longer it goes untested or serviced. In some cases, this inaction can result in the fire suppression system or portable extinguisher not operating at all.

In terms of costs, a gas cylinder installed in a fire suppression system on an average size marine vessel typically contains around 13 kilograms of scheduled extinguishing agent, costing the vessel owner roughly $2,500. If this system discharges due to a lack of adequate maintenance over time, not only does the vessel owner have to pay for a replacement cylinder with new chemical agent, but they must also pay an installation cost – which should be carried out by a licensed fire technician. In simple terms, overhauling an entire fire suppression system far outweighs the cost of having an existing system tested or serviced.

Vessel owners and operators should aim to have their fixed fire suppression system serviced every 12 months, and portable extinguishers every 6 months. These are the recommended timeframes as stated in Australian Standard 1851 – Routine Service of Fire Protection Systems and Equipment.

Vessel owners and operators should also have their fixed fire suppression systems and portable extinguishers undergo pressure testing every five years to ensure there are no leaks to the gas cylinder, and that it will work correctly if required.

Owners and operators should be aware that when gas cylinders become low on pressure, they have a higher chance of discharging chemicals into the atmosphere which can cause depletion to the earth’s ozone layer or contribute to global warming depending on the substance.

The FPIB would encourage all accredited marine surveyors to take a proactive approach in educating vessel owners and operators around the importance of testing and servicing fire suppression equipment on a regular basis. This might be as simple as a two-minute conversation at the conclusion of a survey.

We would recommend that if you are a surveyor and have relationships with owners or operators of vessels belonging to the low or medium risk class, that you please raise the testing and servicing guidelines outlined above. Doing so could save lives, as well as save the owner or operator thousands of dollars if they have to replace a fire suppression system unnecessarily.

Without even realising it, marine vessel owners and operators can actively help to preserve the natural environment by reducing the risk of their fire suppression system equipment unintentionally discharging.

For any concerns or queries, please reach out via ozone@fpib.com.au

Have your say: NSCV C1 consultation

AMSA is now inviting feedback on proposed changes to NSCV Part C1, which contains standards for wheelhouse visibility, escape, accommodation, and personal safety.

The proposed changes include:

- meeting disability accessibility standards

- improved standards for escape routes, escape lighting and signage

- clarified definitions of ‘special working decks’ and ‘working decks’

- further risk management associated with a person falling overboard and the recovery of persons overboard, by improving technology requirements and inclusion of a ‘no-climb’ zone

- a minor relaxation of when toilet and ship sanitation facilities must be fitted

- improved ventilation requirements

- improved safety requirements for pilot vessels

- changes to gangway requirements

- alignment of some requirements with already adopted national and international legislation and standards.

It is proposed that the amended NSCV Part C1 will only apply to newly constructed vessels and vessels that undergo modifications to the arrangement, accommodation, and personal safety aspects of the vessel.

Following consultation, we propose that the new standard will come into effect on 1 January 2023 with a transition period of two years.

Consultation is open until 24 April 2022.

Learn more and submit your feedback

National Law review

The Australian government has commissioned an independent review of Australia’s Domestic Commercial Vessel safety legislation and associated costs and charging arrangements.

The review will be undertaken by an independent expert panel, supported by the Department of Infrastructure, Transport, Regional Development and Communications. AMSA is a stakeholder in this review.

The review will be conducted in two phases, with the first to focus on the National Law framework (Phase 1) and the second to consider national system delivery costs and future funding options (Phase 2).

Submissions for phase 1 of the review are being accepted until 30 March 2022. You can visit the Department of Infrastructure, Transport, Regional Development and Communications ‘have your say’ webpage to make a submission. You can also email submissions to dcvsafetyreview@infratsructure.gov.au.

Discussion of the National Law review has also been added as an agenda topic for the upcoming surveyor workshops. This is so we can hear your view, but note this is not an AMSA review, you need to make comment directly to the Department.

Construction barge safety campaign

AMSA has launched a new safety campaign focusing on the importance of regularly reviewing risks to protect lives on construction barges.

A dedicated campaign website is now available to support owners, operators and individual workers and we encourage you to share the campaign information and advice with your clients.

A series of free workshops covering risk assessment will also be delivered by AMSA, in partnership with state and territory WHS agencies.

The first workshop will be presented in partnership with WorkSafe NSW on 29 March in Drummoyne, Sydney. More workshops in other locations will be announced.

Please recommend this workshop to your clients in the greater Sydney area. For more information and to register online click here.

Exemption 6 has been updated

AMSA has recently updated Exemption 6 Marine Safety (Periodic survey, equipment certification, compass adjustment and liferaft servicing). The new amendments provide greater flexibility for operators when liferafts are being serviced, repaired, or replaced.

DCVs can now operate when a liferaft is out of action, provided there are enough liferafts to accommodate all persons onboard the voyage.

Read more about the update here.