Purpose

While this information is targeted at ships operating on ocean going voyages, the risks apply equally to all vessels carrying BEVs. Vessel types mentioned in this notice are roll-on, roll-off passenger ferries (RORO PAX) and pure car and truck carriers (PCTC). BEVs have been in operation for some time. Current statistics indicate that BEVs are less likely to catch fire than conventional internal combustion engine vehicles. Electric vehicle battery fires are rare. The available data indicate the fire risk is between 60 times greater1 for internal combustion engine (ICE) vehicles. However, the consequences of a BEV fire can be higher.

PCTC Fremantle Highway in July 2023. Photo courtesy of Brookes Bell.

Risks associated with battery-powered vehicles

Increase in weight of the vehicles in comparison with internal combustion engine vehicles of the same footprint. There is an approximate 25% increase in weight compared to vehicles of the same footprint2. This may result in deck loading limitations being exceeded and could adversely affect the stability of the vessel, if not accounted for.

The risk of a fire should a battery cell go into thermal runaway. This is when the heat generated within a battery exceeds the amount of heat that is dissipated to its surroundings. Without intervention (cooling) the internal battery temperature will continue to rise and with this the potential for a fire to spread and an explosion to occur if the resultant gases are allowed to build-up in the space. Most modern BEV’s have an internal cooling system to maintain battery temperature. Modern batteries are designed to vent instead of exploding however the vented gases need to be extracted from any enclosed spaces to avoid pressure building-up and leading to an explosion.

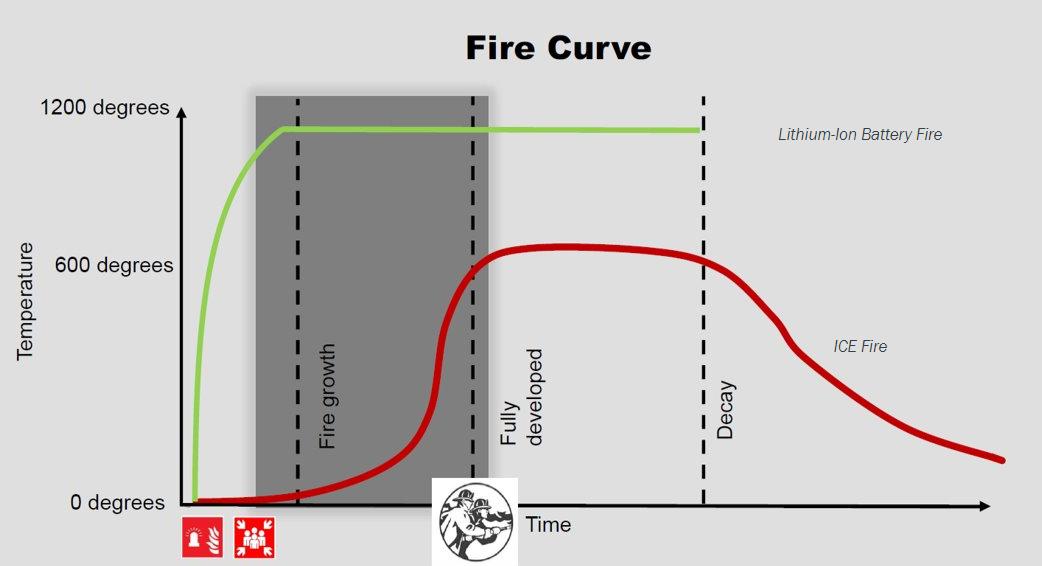

While the likelihood of fires for BEVs is very low compared to fires from internal combustion engines (ICE vehicles are 60 time more likely to catch fire), the fires involving BEVs reach full potential in a shorter period in comparison. Typically flames shoot upwards and outwards simultaneously. BEV fires can reach temperatures of more than 1600 degrees centigrade, hot enough to burn metals like aluminium, commonly used in BEV construction to reduce weight. See below diagram which compares the time taken by BEV fires.

Figure 1: Time taken to reach maximum fire potential. Graph courtesy of Brookes Bell.

The gases produced by BEV fires form a vapour cloud which is both toxic and potentially explosive (hydrogen). For every 1-kilowatt hour (KWh) of battery power, 6000 litres of vapour are produced. A single 55 KWh battery could produce 330,000 litres of vapour.

Significantly increased likelihood of re-ignition of a BEV fire. These fires are a chemical chain reaction, cooling with water slows the reaction but doesn’t stop it completely. Once the cooling is removed, heat from the chemical chain reaction will build up rapidly once again and re-ignition is highly probable.

Detection and prevention of thermal runaway

To assist in the prevention and early detection of thermal runaway ship operators should consider the following:

- As with ICE vehicle, crews should inspect BEVs before and after loading to ensure they are safe to load. With BEV’s crews should ensure no damage has occurred to the battery or if the battery management system is displaying any faults. Some BEVs have a lower ground clearance and may be damaged during loading.

- If damaged, a small amount of fluid may leak from under the vehicle. The battery and drive-unit are liquid-cooled, typically with glycol-based automotive coolant. The coolant is typically either clear or blue in colour and if found leaking, may indicate the high-voltage battery casing has been damaged. Any fluid leakage must be investigated immediately and should prompt further action following investigation.

- Smoke detectors situated on the vehicle decks may take some time to activate as the smoke flow from the thermal runaway can be prevented from reaching detectors due to the physical design of the vehicle decks and the airflow created by ventilation systems.

- Flame detectors are designed to detect the infrared radiation of fires. Such detectors are activated by the presence of flames; thus, it is possible to identify the location of vehicles on fire and respond quickly.

- The installation of closed-circuit television (CCTV) systems with flame recognition capabilities/ thermal detection properties where vehicles, including BEVs, are located can allow early detection of fires. Typically, thermal runaway can be detected at 60-70 degrees centigrade. The position of CCTV systems should be considered. Typically, these are placed fore and aft on a vehicle deck. Operators should consider fitting increased numbers of CCTV cameras with thermal detection capabilities in the athwartship directions to enable rapid detection of thermal runaway. This also allows for the precise location of the fire to be identified.

- Charging stations for BEVs while enroute should be installed in compliance with the SOLAS regulation II-1/45, and SOLAS regulation II-2/20.3. There is further guidance in the IMO Maritime Safety Committee Circular 1615 “Interim Guidelines for Minimizing the Incidence and Consequences of Fires in Ro-Ro Spaces and Special Category Spaces of New and Existing Ro-Ro Passenger Ships”.

- BEVs should be clearly marked and should ideally be located in a designated area known to the crew. The location should, where possible, be on weather decks, away from dangerous goods, have sufficient drainage, adequate separation between vehicles for crew members wearing breathing apparatus to access from multiple access paths and be well clear of all emergency muster points.

- Crew members who conduct safety patrols of the vehicle decks should be made familiar with the early signs of thermal runaway and if possible equipped with thermal handheld detectors. Early indications of thermal runaway are:

- Off-gassing. This is a release of various gases from the battery, including carbon dioxide, carbon monoxide, hydrogen, and volatile organic compounds. During the early phase of gas generation, the off-gases can be heavier than air and accumulate at deck-level or be lighter than air and dissipate or accumulate at deck-head level if the space is not appropriately ventilated. Owing to the various battery chemistries, it is not possible to predict which will dominate.

- A damaged battery can create rapid heating of the battery cells. If you notice hissing, whistling, or popping, a possible sweet chemical smell, black “smoke” (nanoparticles of heavy metals, not smoke) or white vapour coming from the high-voltage battery or the vehicle generally, assume that it is in thermal runaway and take appropriate firefighting measures. Early intervention will minimise the spread of any fire to adjacent vehicles.

- Fire patrols should pay special attention to look for evidence of battery coolant leakage, smoke or heat from the areas of vehicles where a battery is normally located, for example the underside. They should also listen for “popping sounds” which may be indicative of a potential thermal-runaway event.

- Crew should conduct frequent emergency drills and training in the identification and initial response to a BEV battery fire. Early detection and prompt action can minimise the spread of a fire.

MV Fremantle Highway. Photo courtesy of Netherlands Coastguard.

Fire-fighting and BEVs

Vessel operators should consider the following when developing operational plans for fighting fires involving BEVs:

- In the instance of a fire involving a BEV the only way to cool the battery is to use large amounts of water. Typically to fight a conventionally fuelled vehicle fire would require 4000 litres of water. It is estimated that a BEV fire would take a minimum of 10000 litres. The Danish firefighting authorities (DEMA) recommended using water at the rate of 400 litres per minute and limiting the exposure of persons fighting the fire to ten minutes3.

- PCTC’s typically do not have water deluge systems and rely on carbon-dioxide (CO2) systems to extinguish fires on their vehicle decks. It should be noted the significantly increased risk of re-ignition with BEV fires and that CO2 systems do not remove the heat generated from a fire nor extract the highly flammable gasses emitted from a BEV fire.

- CO2 extinguishing systems if applied quickly after the detection and verification/confirmation of a fire have worked successfully to fight fires on board PCTCs. Research projects are ongoing to assess and evaluate the effectiveness of the CO2 extinguishing systems. The International Union of Marine Insurance (IUMI) recommends doubling the capacity of CO2 systems on PCTC’s. Operators should consult with their recognised organisations regarding the amount of CO2 allocated for use in vehicle spaces used to carry BEVs.

- Early detection, confirmation/verification and a short response time are crucial to fight a fire successfully on PCTC. The fixed firefighting systems should be applied first rather than manual firefighting by the crew.

- With RORO PAX ferries the early use of the water deluge system is likely to control the spread of the fire and allow a controlled response. Crew should be familiar with its correct use and the need for the water to be effectively drained from the vehicle decks so as not to adversely affect the stability of the vessel. The highly flammable vapour emitted from the BEV fire should also be ventilated from any enclosed spaces to minimise the risk of explosion. RORO PAX vessel master's should closely monitor the flow of vapour from the BEV fire and manoeuvre the vessel to ensure the vapour is moved away from passenger areas and emergency stations such as lifeboat launching and embarkation areas.

- Other methods to restrict the flame and heat spread such as specialist vehicle fire blankets or other specialist textile boundaries may be used until sufficient water quantity is available. However, in using these blankets / specialist boundaries careful consideration must first be given to the specific risks that may be encountered. These include restricted access around vehicles on a ro-ro deck and the rapid escalation of the BEV fire including gases and smoke that may reduce visibility and produce extreme heat for personnel approaching the fire. These fire blankets may be best suited as a precautionary measure deployed where a vehicle has been identified as being at increased fire risk e.g., if battery coolant is found leaking during routine fire patrol. While vehicle fire blankets will contain flame, the thermal-runaway event will continue.

- The fumes produced by BEV fires are toxic and emergency teams responding to fires should be equipped with fire-fighting suits that comply with SOLAS II-2 regulation 10.10. Decontamination procedures should also be incorporated in fire-fighting plans as BEV fires may create hydrogen fluoride. This is a hazardous substance that may penetrate protective clothing. It is highly corrosive and toxic and will cause chemical burns if it permeates through clothing and comes in to contact with skin. A ship’s procedures for dealing with clothing and equipment exposed to BEV fires should address this risk.

- BEV crews should have additional equipment to ensure their safety when fighting BEV fires, including:

- Defibrillator

- Gloves rated for high voltage use

- Gas detector to analyse the atmosphere for explosive gases.

- Until the chemical chain reaction exhausts itself, there is significant risk of re-ignition. A fully-equipped fire-fighting team should be monitoring the fire site and able to respond immediately until the vehicle is removed from the ship.

- Vessel operators should consider providing crew with additional safety equipment (such as full-face respirators) to protect them from the toxic vapour produced by BEV fires when conducting emergency duties such as preparing lifeboats for launching. spirators) to protect them from the toxic vapour produced by BEV fires when conducting emergency duties such as preparing lifeboats for launching.

Guidelines

- https://lashfire.eu/

- MGN 653 (M) Amendment 1 electric vehicles onboard passenger roll-on/roll-off (ro-ro) ferries - GOV.UK

- ELBAS project

- MSC Circulars / MSC.1/Circ.1615

- EMSA guidance

Disclaimer

This marine notice provides general information and is for awareness only. It should not be relied upon for decision making purposes - ship owners, operators, masters and crew should undertake their own risk assessments and act accordingly.

1 https://www.autoinsuranceez.com/gas-vs-electric-car-fires/