Once spilled into the water or stranded on a coast, oil begins to change, which has implications for the use of dispersants. This process is known as weathering. It is a complex process as the chemical and physical properties of oils interact with external factors and is not easily explained. The type and rate of weathering is affected by:

- oil type and chemical composition

- oil slick thickness

- temperature of seawater and air

- wind speed and sea state.

Detailed explanations of weathering can be found in the related information section below.

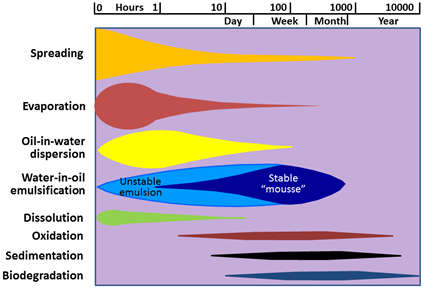

There are eight main weathering processes; four tend to occur early, and have a significant effect on dispersability.

Spreading

- Oil begins to spread over the sea surface as soon as it is spilled. This increases the size of the slick, changes its shape and local thickness

- Viscosity, determined mainly by oil chemistry and temperature is the primary driver

- After a few hours, under the influence of currents, winds, waves and water turbulence, the slick can be patchy, of variable thickness and so presents a more difficult dispersant spraying target

Evaporation

- Evaporation begins as soon as the oil is spilled

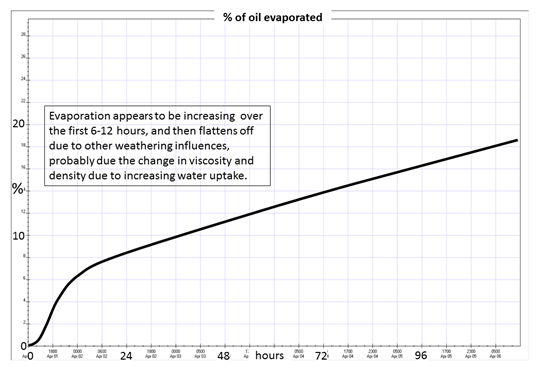

- Evaporation rates generally depend on the percentage of volatile compounds in the oil, the local temperature and wind speed

- Evaporation of distilled fuels (diesel, gasoline, kerosene) is faster as they have fewer, if any heavier hydrocarbons in them

- Residual fuels (HFO or IFO380/180) have fewer volatile components and evaporate less

- Crude oil types can span the entire range

Natural dispersion

- Sea surface conditions can cause oil slicks to begin to disperse and dissolve

- Small droplets form and become mixed into the upper water levels. Their small size and volume means they are effectively neutrally buoyant and do not refloat easily

- Larger droplets tend to refloat and form slicks or films

- Low viscosity oils tend to disperse most easily

- Addition of chemical dispersants can significantly aid natural dispersion

Emulsification

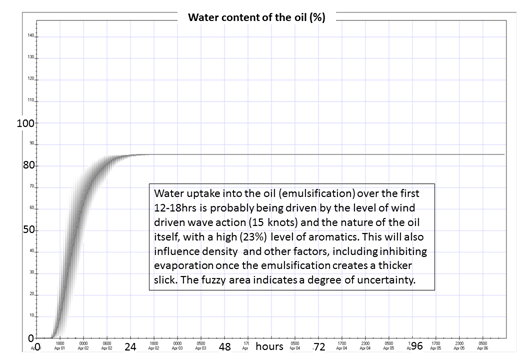

- An emulsion is the combination of two liquids, one suspended as small droplets in the other

- Emulsification occurs when seawater droplets become suspended in oil through physical mixing. This forms a very thick product known as mousse which can increase the oily volume by 3-5 times that of the original oil spill

- Mousse formation slows and delays other weathering processes and creates slicks that are too thick for most dispersants to be effective

The below weathering processes tend to have little influence on dispersant decisions or operations.

Dissolution

- Water soluble compounds in an oil can dissolve into the surrounding water. Any components likely to dissolve are also likely to evaporate at a much faster rate

Oxidation

- Oils reacting with oxygen very slowly either break down into more soluble compounds or form thick tarry compounds. A tarry crust inhibits other weathering processes and tends to promote the formation of tarballs

Sedimentation/sinking

- If the oil is heavy enough to sink, either at the time of the spill, or due to weathering outcomes or contact with suspended sediments, dispersants are not very useful

Biodegradation

- Micro-organisms can eat oil. This is known as biodegradation and can take days to years. Dispersion of oil in the water in small droplets can enhance this process.

The diagram below represents the weathering fate of a typical crude oil spill, showing changes in the relative importance of weathering process with time (from hours to years). The width of the band indicates the relative importance of the process.

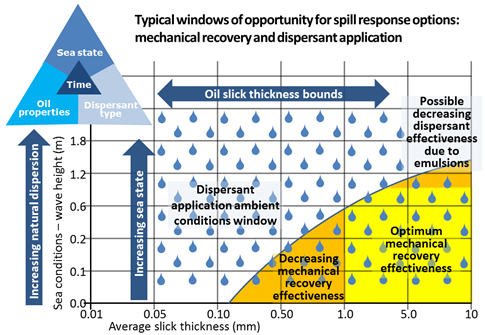

In general, dispersants tend to work best with lighter, thinner oils, in more energetic conditions. So in general, it is best to apply dispersants earlier, if conditions are appropriate.

Dispersant application is less limited by ambient conditions than other options. Mechanical recovery can be limited by sea state and slick thickness.

Four factors determine whether a chemical dispersant operation can be successful:

- Oil properties change as oil weathers

- Ambient conditions generate mixing energy

- The dispersant type available and logistics around transport and application need to be considered

- Timing; the degree of weathering, logistical delays and changing sea state, can all reduce effectiveness

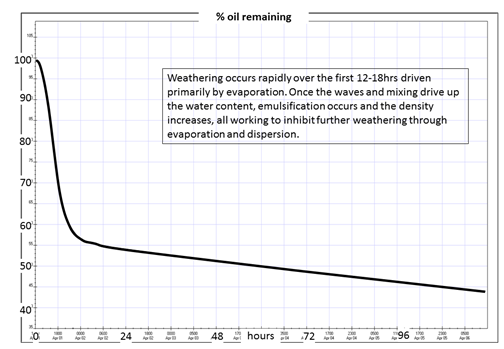

The complexity created by the interactions of the oil type, the weathering process and ambient conditions has resulted in the development of sophisticated computer models. These models are able to make predictions about how weathering might progress over time, and resulting response options, like dispersant application. However, the results are modelled predictions, and caution should always be used in interpreting results.

Effect of wind, waves and mixing energy on spilled oil properties, behaviour and fate

As these influence and effect each other, the complexity of interactions is often hard to predict. There are some general rules of thumb, but they need to be applied with caution and experience, hence the use of programs like Automated Data Inquiry for Oil Spills (ADIOS), as shown below.

All other things being equal:

- Increasing wind speed and wave action tends to increase the loss of light oil components through evaporation and dispersion and sometime dissolution.

- Increasing wave action can increase mixing energy to increase emulsification, but there may be thresholds where the stability of the emulsion can break down with increasing energy input.

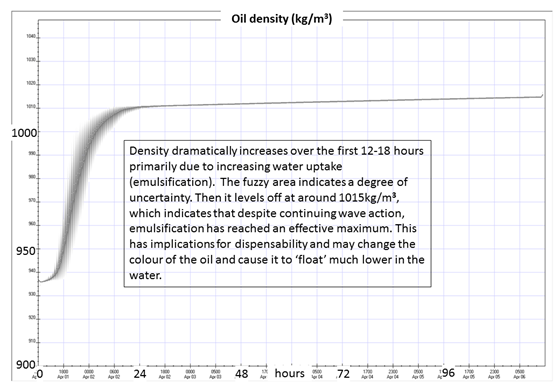

- Increasing emulsification, as well as evaporation of the light products, leads to increasing density.

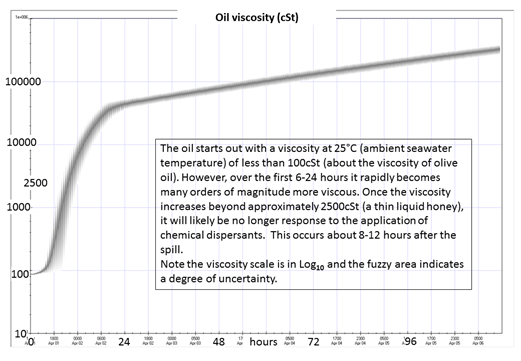

- Increasing density and emulsification tends to lead to increasing viscosity.

- Increasing viscosity and density tend to inhibit evaporation and dispersion.

- Increasing water temperature tends to promote evaporation, but less than increasing wind speeds.

- Exceeding an oil viscosity threshold of between 2000 and 2500 cSt can result in chemical dispersants becoming completely ineffective.

If oil weathering is suspected in an oil spill incident, then modelling changing oil properties using ADIOS is strongly recommended. Modelling can be used to assess changes in viscosity, natural dispersion, evaporation, density, potential to emulsify, etc. It can then determine the window of opportunity for use of chemical dispersants.

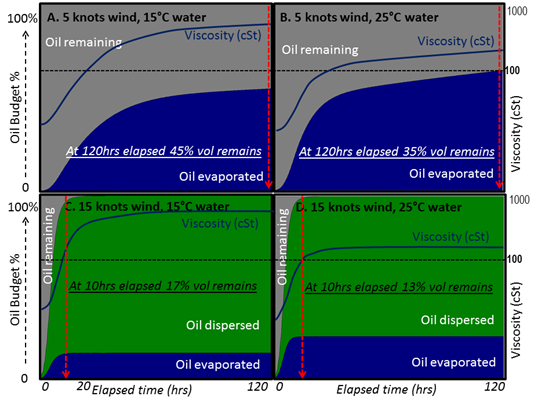

Examples of how wind speed and water temperature affect expected weathering

The following figures, derived from ADIOS2 analyses, demonstrate the influences of different ambient conditions on marine diesel and intermediate fuel oil spills, to show how these affect weathering and fate. For a nominal spill volume of 100 cubic metres, two local wind speeds (constant 5 knots and 15 knots) in two water temperatures (15°C and 25°C) were used to predict changes over five days (120 hours).

Marine diesel

For a relatively light oil like refined marine automotive diesel (API 31.6; a pour point -12°C; and viscosity of 16.8 cSt @ 15°C), ADIOS predicts that at lower wind speeds (5 knots) the biggest weathering effects will come from evaporation (the blue area below), while with more mixing energy (at 15 knots) the biggest factor will be natural dispersion. Water temperature has little effect. Viscosity starts low and remains well below 1000cSt throughout.

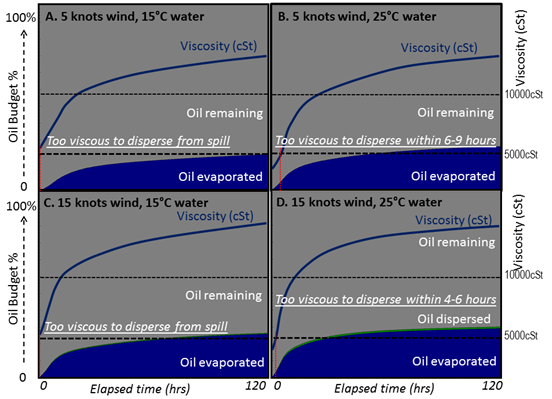

Marine intermediate fuel oil (IFO180)

For IFO180, a much heavier refined product with a molasses-like quality (API 14.7; unknown but very high pour point; viscosity of 2404cSt @ 15°C, with 51 per cent aromatics, 10 per cent asphaltenes, and 11 per cent resins) the predictions are very different. Right from the start the spilled IFO180 is likely to be too thick to disperse, and as the aromatic and lighter components evaporate, this will quickly compound. Neither the different water temperatures nor the different winds speeds (wave mixing energies) have significant influence on this oil, with all scenarios resulting in around 75-80 per cent of the oil remaining after 120 hours.

- Australian dispersant stock suitability

Table 1. General guide to suitability of National Plan dispersants

Product name (OSCA register) Type / chemistry Starting dispersant to oil (DOR) application ratio Type of oils for use on Deliverable from: In which stockpile: Dasic Slickgone NS Type 3, Water-dilutable concentrate, anionic surfactant 1:25 Light – possible

Medium – yes

Heavy - yes/possibleBoat (conc)

Water induction

Small Aircraft (conc)AMSA (National Plan)

AMOSCDasic Slickgone EW Type 3, Water-dilutable concentrate, anionic surfactant 1:25 Light – possible

Medium – yes

Heavy - yes/possibleBoat (conc)

Water induction

Small Aircraft (conc)AMSA (National Plan) Ardrox 6120 Type 2/3, Water-dilutable concentrate 1:25 Light – possible

Medium – yes

Heavy – yes/possibleBoat (conc)

Water induction

Small Aircraft (conc)AMOSC only Corexit 9500 Type 3, Hydrocarbon Based 1:10 – 1:50 Light – yes

Medium – yes

Heavy - yes/possibleBoat (conc)

Water induction

Small Aircraft (conc)AMOSC only Corexit 9527 Type 3, Water-dilutable concentrate, non-ionic surfactant3 1:20 – 1:30 Light – possible

Medium – yes

Heavy – yes/possibleBoat (conc)

Water induction

Small Aircraft (conc)AMOSC only

(Specific inventory held by ExxonMobil)Dispersants not held in AMSA or AMOSC

The Finasol OSR 51/52 OSCA-Registered dispersants are not, as at January 2019, held in AMSA or AMOSC (including industry) Australian dispersant stockpiles. OSRL ,in Singapore, holds 350,000 litres each of Finasol OSR 52 and Dasic Slickgone NS, in their Global Dispersant Stockpile. If imported, both are acceptable for use in a National Plan response.

(OSCA register) Type / chemistry Starting dispersant to oil (DOR) application ratio Type of oils for use on Deliverable from: In which stockpile: Total Finasol OSR51 or OSR52 Type 2/3, Water-dilutable concentrate, anionic and non-ionic surfactant 1:10 -1:25 Light – possible

Medium – yes

Heavy - yes/possibleBoat (conc)

Water induction

Small Aircraft (conc)OSRL Singapore

(through AMSA)

ADIOS2 Computer modelling of oil weathering

We recommend responders in Australia use the NOAA ADIOS2 Tool (Automated Data Inquiry for Oil Spills version – soon to be version 3 as a web tool) to model the oil weathering and to inform the fate of the oil.

Information required to run the model includes:

- oil name/product type (approximately 800 oils are in the current database, including many Australian oils and fuels)

- amount of oil spilled

- instantaneous or continuous spill

- wind speed (constant or time dependent)

- wave heights (constant or time dependent)

- water temperature

- water salinity

- emulsification constant (if known).

Two types of output can be generated:

- Time dependent graphs of:

- viscosity

- density

- water content

- evaporation

- natural dispersion

- airborne benzene concentration in ppm (if relevant).

- Oil budget table of oil mass balance.

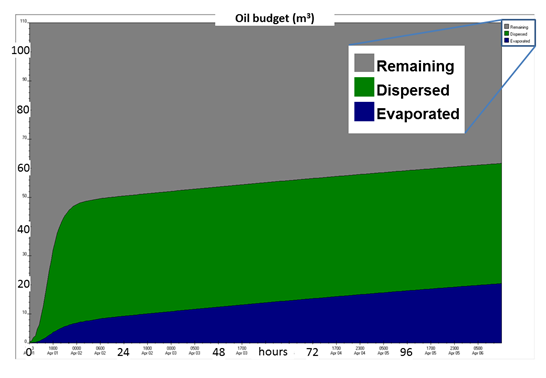

To demonstrate the effect of these conditions on the physical properties of a selection of oils, we ran the ADIOS computer software on two main risk oils: a marine diesel and an intermediate fuel oil (IFO-180); and a West Australian crude to demonstrate the output types.

Understanding and interpreting ADIOS outputs

ADIOS can produce output in various ways, including graphs like those shown in Figures 3 and 4 above, showing each of the various weathering processes and an overall outcome for the time period sought. It also provides a mass balance table and a text file with the inputs selected and any commentary about the oil and its behaviour. Below is a series of the outputs for a Western Australian crude oil being produced off the Dampier coast.

Table 2. The spill scenario, and calculated oil parameters for the conditions provided

| Property or parameter | ADIOS data or commentary |

|---|---|

| Oil name | Stag, Apache, Western Australia |

| Oil type | Crude |

| API | 18.3 |

| Pour point | -30°C |

| Flash point | greater than 100°C |

| Density | 0.937 g/cc @ 25°C |

| Viscosity | 86 cSt @ 25°C |

| Aromatics | 23 per cent by weight |

| Wind and wave conditions | 15 knots from 0 degrees (N) |

| Water properties | 25°C; 32 ppt salinity; 5 g/m3 sediment load (oceanic) |

| Release information | Instantaneous of 100 m3 at 1200hrs 01/04/16 |

| Emulsification | Mousse begins to form when 5 per cent of oil has evaporated |

Note that the table will present some very pertinent data—specifically density and viscosity—to make it relevant to the local sea temperature, in this case 25°C, although the data provided in the oil parameters table in ADIOS may have these data relevant for other temperatures. This greatly assists the responder as the conversions to ambient temperatures have been done for you.

Below in Figures 5-10 and Table 2 are the various relevant outputs for the 120 hour projection, with notes attached and embedded.

Another form of output from ADIOS is a mass balance table over a period of 120 hours.

Table 3. The spill scenario oil budget table, for the parameters provided and calculated.

| Hours into the spill | Amount released m3 | Evaporated percent | Dispersed percent | Remaining percent |

|---|---|---|---|---|

| 1 | 100 | 0 | 1 | 99 |

| 2 | 100 | 0 | 2 | 98 |

| 4 | 100 | 1 | 10 | 89 |

| 6 | 100 | 3 | 23 | 74 |

| 12 | 100 | 6 | 37 | 57 |

| 24 | 100 | 8 | 38 | 54 |

| 36 | 100 | 10 | 38 | 53 |

| 48 | 100 | 11 | 38 | 51 |

| 72 | 100 | 14 | 38 | 49 |

| 96 | 100 | 16 | 38 | 46 |

| 120 | 100 | 19 | 38 | 44 |