This Marine Notice reminds shipowners, operators, masters, crews, recognised organisations, marine pilots and pilotage providers about their obligation to provide and ensure continued safe pilot transfer arrangements on ships.

Background

Since November 2017 several pilots’ lives were placed at risk, in multiple separate incidents where a man rope parted, or its securing point failed. Additionally, AMSA received several incident reports on safety issues related to pilot transfer arrangements.

Ship owners, operators, masters and crews are reminded that pilot transfer arrangements, including pilot ladders, must comply with Marine Order 21 (Safety and emergency arrangements) 2016 (MO21) which sets out Australia’s obligations under the International Convention for the Safety of Life at Sea (SOLAS) Chapter V Regulation 23 (SOLAS V/23).

- Pilot transfer arrangement standards

Whenever a pilot or other person embarks or disembarks from a ship by ladder, they entrust their safety to the pilot transfer arrangements provided by the ship and the pilot boat crew.

SOLAS V/23 sets out the minimum standards for pilot transfer arrangements on ships on or after 1 July 2012. The International Maritime Organisation (IMO) standards related to pilot transfer arrangements are found in:

- IMO Resolution A.1045(27) – Pilot transfer arrangements.

- IMO Resolution A.1108(29) – Amendments to the Recommendations on Pilot Transfer Arrangements (Resolution A.1045(27)).

- MSC.1/Circ. 1428 – Pilot Transfer Arrangements – Required boarding arrangements for pilots

- MSC.1/Circ.1495/Rev.1. – Unified Interpretation of SOLAS Regulation V/23.3.3 on Pilot Transfer Arrangements

SOLAS V/23.2.3 also states a pilot ladder shall be certified by the manufacturer as complying with SOLAS V/23 or “with an international standard acceptable to the Organization” and refers to ISO 799-1:2019 “Ships and marine technology – pilot ladders”. Compliance with this particular provision of SOLAS V/23 can be met when a manufacturer has certified the pilot ladder complies with either of the IMO or ISO standards, noting they are not identical.

Where a pilot ladder has been certified under the ISO standard, AMSA expects that the ladder is strength tested according to the standard. Where this test has not been conducted within 30 months, the ladder should not be used until the test is conducted, or the ladder is replaced.

When purchasing a pilot ladder, care should be exercised that the product supplied actually meets the above requirements - relying on the manufacturer’s documentation may not be sufficient in some cases. If in doubt, the ship’s Recognised Organisation should be requested to confirm that the ladder meets the minimum standards.

- Pilot transfer arrangements

IMO Circular MSC.1/Circ.1428 illustrates the pilot transfer arrangements required by SOLAS V/23.

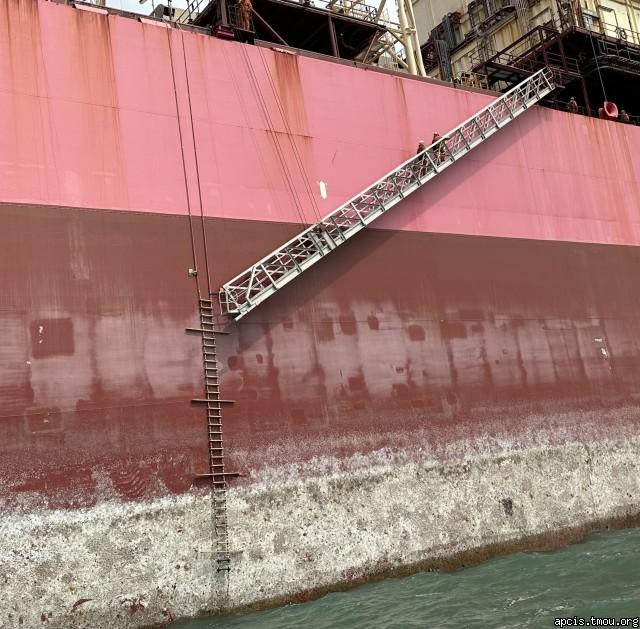

When using a combination pilot ladder arrangement, the pilot ladder and accommodation ladder are required to be secured to the ship’s side. A common means of securing both the pilot ladder and accommodation ladders is with magnetic pads (refer to photo 1 below as an example).

Photo 1: Example of securing both the pilot ladder and accommodation ladders with magnetic pads (Reproduced with permission from Fremantle Ports).

Photo 1: Example of securing both the pilot ladder and accommodation ladders with magnetic pads (Reproduced with permission from Fremantle Ports).Clear and efficient communication with the pilot boat master is essential to ensure the safety of the pilot transfer arrangements before a person uses the ladder. The pilot boat master is best positioned to judge correct height of the bottom of the ladder and identify any potential issues with the ladder or ropes once in place.

One common issue found is that the pilot ladder does not extend the required 2.0 m past the accommodation platform when a combination arrangement is used. Photo 2 illustrates an example of a pilot ladder not extending the required height past the platform.

Photo 2: Example of non-compliant combination pilot ladder arrangements.

Photo 2: Example of non-compliant combination pilot ladder arrangements.As shown in photos 2 and 3 persons cannot climb the pilot ladder to a level where they can move safely onto the accommodation ladder.

Photo 3: Person unable to safely access accommodation ladder platform from pilot ladder.

Securing of Pilot Transfer Arrangements

The pilot ladder is normally secured at its thimble end with shackles. However, due to the varying freeboard at specific loading conditions, the pilot ladder cannot always be secured at full length by the thimble ends. Under such circumstances it must be secured at an intermediate length. That can only be done in a safe way by ensuring that the weight of the ladder is transferred from ladder’s side ropes to the approved strong point on deck directly.

The ladder’s steps, spreaders or chocks should not be used to carry the weight of the ladder as they are not designed for this and do not have sufficient strength. For this reason, shackles, bars and tongues should not be used to secure the ladder to the deck. They will damage the ladder and put weight on the parts which are not designed to carry the weight.

Photo 4 shows an example of an unsafe use of shackles to secure pilot ladders.

Photo 4: Unsafe pilot ladder securing arrangements (Reproduced with permission from Fremantle Ports).

Photo 5: Unsafe pilot ladder securing arrangements.

Photos 5 shows the pilot ladder being secured to the strong point by using a shackle passed through the pilot ladder side ropes. This puts increased load on the single part of the side rope and the chock securing arrangements.

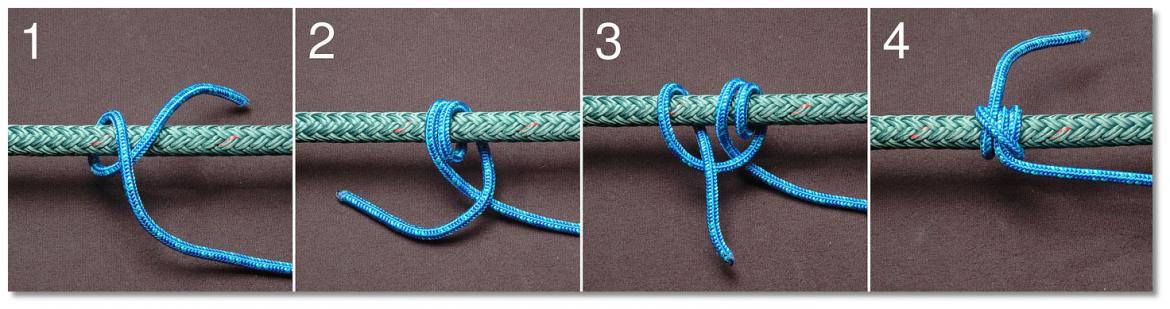

It is common industry practice to use a rope stopper usually in the form of a rolling hitch knot between the pilot ladder sides ropes and the approved strong point on the main deck. This will transfer the weight of the ladder arrangement directly onto the designated strong point and will not damage the ladder.

It is suggested that two strong (at least 2 x 24 kN) manila ropes be used to secure the pilot ladder. Photo 6 illustrates a method of tying a rolling hitch knot.

Photo 6: The rolling hitch knot. (Reproduced with permission from Fremantle Ports).

Photo 7 provides an example of rolling hitch knots being used to secure pilot ladders to approved main deck strong points.

Photo 7: Rolling hitch knots being used to secure pilot ladders to approved main deck strong points (Reproduced with permission from Fremantle Ports).

- Inspection and Maintenance

Ongoing inspection and maintenance of pilot boarding arrangements are an essential part of ensuring their continued safe operation.

Paragraph 10.1 of Part A of the International Safety Management Code (ISM) requires ship operators establish procedures to ensure a ship is maintained in conformity with the relevant rules and regulations, including pilot transfer arrangements.

Such procedures should include regular inspections of the pilot transfer arrangements and storage to prevent damage of such equipment when not in use.

Photo 8: Pilot ladder where side ropes parted when in use (Reproduced with permission of the MAIB).

Common areas of defects can be the thimble ends of the pilot ladder. Corroded end point thimbles as illustrated in photo 9, can damage the side ropes leading to failure.

Photo 9: Example of corroded end point thimbles (Reproduced with permission from Fremantle Ports).

Another common area is the frayed or damaged side ropes as illustrated in photo 10. These should be detected during routine visual inspections.

Photo 10: Frayed side rope.

If side ropes are frayed, or in any way degraded the ladder should not be used.

The man ropes which are used as part of the arrangements should also be regularly inspected. There have been two recent incidents of man ropes parting during transfer operations. Though rope type is not specified in SOLAS the Australasian Marine Pilots Institute recommends grade 1 manila be used.

These should be tagged and included in onboard inspection and maintenance procedures. Good practice dictates these should be removed from service at the same intervals of not more than 30 months or sooner if required.

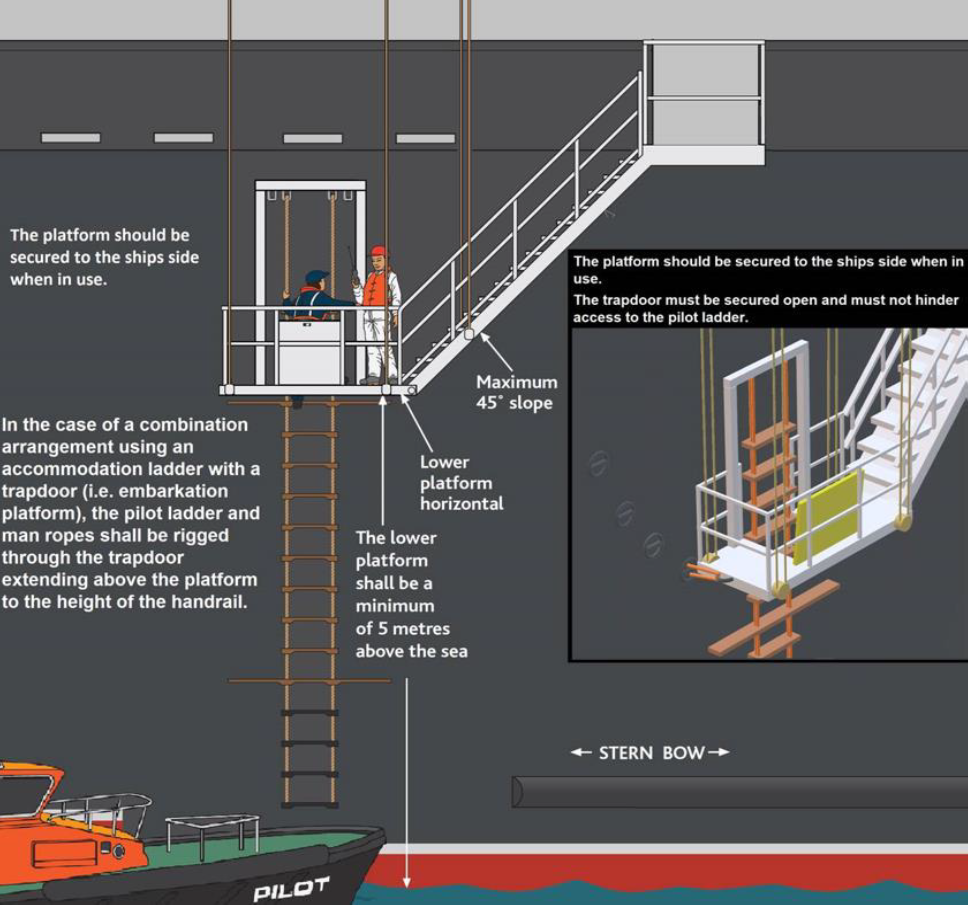

Trap door arrangements and use of combinations ladder

There has been an increase in ships fitted with trapdoor arrangements. The additional requirement for their use is "the pilot ladder and man ropes shall be rigged through the trapdoor extending above the platform to the height of the handrail”.

Figure 1: Pilot card depicting trap door arrangements.

If the pilot ladder and man ropes are not rigged through the trapdoor this creates an unsafe arrangement for persons as illustrated in photo 11.

[

[Photo 11: Unsafe trapdoor pilot transfer arrangement.

- Responsibility for safe pilot transfer arrangements

Responsibility for safe practices for personnel transfers rests with each person involved in the activity including the ship owners, operators, master and crew, pilotage providers, pilots and pilot boat crew, as well as the person being transferred. All parties should observe both the spirit and intent of the regulations, to ensure safety is not compromised.

Where a person suspects that the pilot transfer arrangement provided is unsafe, they should refuse to use the arrangement until it is made safe by the master and crew and report the circumstances to AMSA and their employer. Where such situations occur, AMSA will endeavour to follow-up to determine the cause and actions taken. Where a ship is not calling into an Australian port, AMSA will follow up with the flag State.

When not in use, the pilot ladder and man ropes should be stowed appropriately to avoid exposure to contaminants or other elements that will degrade the ladder and man ropes. The ladder and man ropes should be regularly inspected by the ship’s crew to ensure they remain ready for use.

- Additional information

The I... Pilot Ladder Poster provides further guidance on pilot transfer arrangements This and other useful guidance material are available on the AMSA website and in the AMSA Pilot mobile App.

- Implementation of standards

When conducting port State control (PSC) inspections, AMSA inspectors will pay particular attention to the material state of all equipment and the implementation of Marine Order 21, Res.A.1045(27) as amended by Res.A.1108(29), ISO 799-1:2019, MSC.1/Circ.1428 and MSC.1/Circ.1495/Rev.1. The relevant IMO circulars and resolutions can be obtained from AMSA or www.imo.org.

During recent PSC inspections AMSA surveyors have noted pilot ladders which have been constructed with splices in the side ropes.

Photo 12: Example of non-compliant pilot ladder with splices in side ropes.

Pilot ladders constructed like this are considered non-compliant by AMSA. Ship operators and masters are recommended to check their pilot ladders for splices in the side ropes. It should be noted by operators coming to Australian ports that the availability of compliant pilot ladders is limited in Australia. To prevent avoidable delays operators are recommended to have spare compliant pilot transfer arrangements onboard.

Compliance with the referenced standards does not of itself assure safety in each case. A pilot transfer arrangement that complies with the standards but is incorrectly rigged still presents a hazard to anyone using the arrangement. Crew members assigned to rig a pilot transfer arrangement should be sufficiently familiar with the task. The master or responsible officer supervising the rigging of the pilot transfer arrangements should assess whether supplementary measures, such as lifejackets, harnesses, lifelines be made available to enhance the safety of personnel rigging the pilot transfer arrangement. Where a pilot transfer arrangement is rigged incorrectly, this may contribute to evidence that the master or crew are not familiar with essential shipboard procedures relating to the safety of the ship. A number of documents have been produced as referenced in this Marine Notice to assist in the rigging of a pilot transfer arrangement correctly.