Victoria—changes to domestic commercial vessel services

To help you understand how these changes affect you, we’ve outlined them below.

Certificates of competency

| Transport Safety Victoria (TSV) | AMSA—from 1 July |

|---|---|

|

|

Certificates of operation

| Transport Safety Victoria (TSV) | AMSA—from 1 July |

|---|---|

|

|

Certificates of survey

| Transport Safety Victoria (TSV) | AMSA—from 1 July |

|---|---|

Initial survey

| Initial survey

|

Periodic survey and renewals

| Periodic survey and renewals

|

Non-survey vessels

| Transport Safety Victoria (TSV) | AMSA—from 1 July |

|---|---|

|

|

Exemptions and equivalent means of compliance

| Transport Safety Victoria (TSV) | AMSA—from 1 July |

|---|---|

|

|

Maritime Safety Victoria, as a branch of Transport Safety Victoria, will continue in its role as the marine safety regulator in relation to matters that include local waterways management, local knowledge certification, pilotage and harbour master licensing, as well as the regulation of recreational boating activity.

MSV will also continue to undertake investigations into breaches of National Law through the provision of compliance and enforcement services as part of an agreement with AMSA, and in the regulation of safety duty holders such as port operators, pilotage service providers and towage providers through the application of Victorian marine safety law.

Requesting records lodged in Victoria

From 1 July 2018, the national system changes the way records related to domestic commercial vessels submitted to Transport Safety Victoria (TSV) are accessed. AMSA and TSV have agreed to the following process to assist with requests for records:

| How to request records in Victoria | |

|---|---|

| How do I request records submitted to TSV after 1 July 2013? | Public requests for records should go directly to AMSA via the Freedom of Information process or Information release authorisation form 664. |

| How do I request records submitted to TSV before 1 July 2013? | Public requests for records should go directly to TSV. They will advise of any fees associated with document retrieval. More information can be found on the TSV website. |

| What if my records span both before and after 1 July 2013? | If your request spans records submitted before and after 1 July 2013, please make requests for records submitted before 1 July 2013 to TSV and records submitted after 1 July 2013 to AMSA using the process outlined above. |

Survey Matter—September 2021

In this edition

- Audits and application assessments

- Submission of survey reports

- Structural fire protection

- Out of water survey requirements

- Navigation light requirements

- Lines plans/hull model requirements

- Autonomous vessels in Australia

- Nitrogen oxide (NOx) emission requirements for marine diesel engines on DCVs

- The AMSA National Compliance Plan 2021-22 is now available

- We welcome your feedback

Audits and application assessments

AMSA audits recently accredited marine surveyors to ensure the correct procedures and protocols set out in the National Law - Marine Surveyors Accreditation Guidance Manual (SAGM) and the Marine Safety (Domestic Commercial Vessel) National Law Regulation 2013 (the regulations) are followed. These audits identify issues that may arise in the early stages of a surveyor's activity.

Observations and non-conformances will be provided in writing to the surveyor for action.

Audits also occur because of complaints received or non-conformances detected during our assessment of survey applications. The three cases below are examples where major non-conformances were identified.

A certificate of survey application for a new build 2B vessel was refused when several major non-conformances were identified. The non-conformances included, but were not limited to:

- The vessel was fitted with non-compliant structural fire protection material

- The fuel tank did not comply with NSCV C5A

- The damaged stability did not comply with NSCV C6B

- The vessel was fitted with a stepped collision bulkhead that does not comply with NSCV C6B 7.3.6

- The stability documentation was missing critical detail and did not comply with NSCV C6C.

The surveyors involved were counselled for contravention of conditions of accreditation. The vessel has since undergone modifications and a new application for a certificate of survey has been submitted.

An AMSA inspection identified a 3B vessel had undergone a major refit. The vessel had permanent ballast removed and major hull and structure replacements were carried out. Fish linings, tanks and freezers were also removed, and the vessel’s stability needed to be reassessed. The accredited surveyor made an error in assuming these works could be undertaken as a renewal survey instead of an initial survey to the transitional vessel standards.

The vessel’s certificate of survey was suspended without a show cause notice as there was clear intention to operate the vessel without a revised stability assessment. The vessel remains unable to operate without contravening S11(1) (h) of Marine Order 503, pending an initial survey.

The accredited surveyor was issued a notice of decision letter refusing a further time period to renew their accreditation under the National Law. The surveyor had failed to apply to renew their accreditation within the timeframes set out by the regulations. The surveyor is no longer accredited after they chose not to submit an initial application and undergo an interview.

AMSA conducted inspections on two 2C sister vessels after receiving a complaint. Major non-conformances were identified following a physical practical stability test of the vessels.

The surveyor had initial survey categories revoked following an audit and show cause process. The certificates of survey were revoked for both vessels, and the owner has settled a claim against the builder and surveyor involved.

Submission of survey reports

AMSA will stop receiving emailed survey reports from 1/12/2021. This means accredited marine surveyors and Recognised Organisation surveyors need to submit their reports and recommendations directly into MARS from this date. We are making this change so that our stakeholders (your clients) receive their certification as soon as possible. This change will increase the efficiency of certification processes.

To prepare for this change surveyors will need to ensure your MARS login details (username and password) are current. You will need to download the free ‘VIP Access’ app to your desktop or mobile device. Chapter 3 of the MARS user guide contains the steps to get set up and log in. The user guide is available on the AMSA website here. If you need help setting up, you can email mars.support@amsa.gov.au for assistance.

You should review the rest of the user guide to ensure you are familiar with uploading survey reports directly into MARS. If you currently submit your reports via email, you now have almost three months to transition to lodging reports directly into MARS.

Please note the MARS user guide and associated web pages will be updated to reflect the change in process.

Can one of my employees access MARS and upload surveys on my behalf?

Yes, AMSA provides the option to set up company access so an administrative representative can claim and enter surveys on behalf of a surveyor. Send an email to DCVSurvey@amsa.gov.au if you would like to set up company access.

Does this apply to ALL survey reports?

There are some exceptions to the rule. AMSA will accept emailed submissions when:

- A licensed electrical contractor, who isn’t an accredited marine surveyor, conducts an electrical survey.

- A surveyor provides a recommendation in support of an EX02 application or as part of an engine change notification.

- An accredited marine surveyor who doesn’t hold the required category to claim a code asks for the survey activity to be marked ‘not required’ (with sufficient justification).

What if I conduct an additional survey outside the vessel’s survey cycle?

If you conduct an additional survey that doesn’t align with a vessels survey cycle, for example a repair survey, you can email DCVApplications@amsa.gov.au and ask for a code to be generated. This process also applies for surveys conducted on vessels that aren’t required to hold a certificate of survey, for example vessels operating under EX02 Division 5.

What about surveys for vessels greater than 35 metres?

There is no change to the process already in place. If an accredited surveyor conducts a survey on a vessel greater than 35 metres they must email DCVSurvey@amsa.gov.au and provide:

- The vessel name and UVI

- The survey code(s)

- The reason a Recognised Organisation doesn’t need to survey the vessel (i.e. it is an existing vessel not in class at 01/07/2013)

Any questions about this update can be directed to DCVSurvey@amsa.gov.au

Structural fire protection

AMSA continues to receive recommendations from surveyors where non-compliant structural fire protection has been fitted to vessels. These non-conformances have significant impacts for builders, surveyors and vessel owners. AMSA recently refused an application for a certificate of survey for a new build vessel fitted with non-compliant structural fire protection, among other non-conformances.

We wrote about passive fire protection measures in the April 2020 edition of Survey Matters. The information is reproduced below to reiterate the importance of compliant structural fire protection.

Structural fire protection is installed on the vessel structure to contain or slow the spread of fire. It includes the installation of fire-resistant bulkheads, deck heads, decks and doors.

The primary aims of structural fire protection are:

- Prevent or delay the spread of fire, smoke and heat within high-risk spaces.

- Protect essential systems and spaces to enable evacuation from the immediate area. This also ensures persons on board can reach muster stations and then abandon ship, should the fire become unmanageable.

- Provide redundancy and work alongside active fire protection systems. This avoids vulnerability arising from over-reliance on a single measure.

Passive structural fire protection works in four main ways:

1. Protects structural elements

Structural fire protection guards essential components and compartments against fire and thermal heat, to maintain structural integrity.

2. Compartmentation

Compartmentation includes fire-rated divisions or compartments, bulkheads, deck heads, and smoke barriers. It seeks to contain the spread of fire, thermal mass and smoke. Fire can be contained within the machinery space, for example, if the bulkheads and decks are sufficiently protected.

3. Opening Protection

Fire doors and fire-resistant penetrations installed in openings aim to maintain fire-resistance. They work together to form an effective smoke and fire barrier.

4. Fire stopping materials

These materials generally withstand temperatures exceeding 1200°C for extended time periods. This limits fire spread.

Note: It’s common to see a fire-rated division penetrated during modifications. Workers may leave hidden holes in the division as they perform maintenance and upgrades. Surveyors need to pay attention to fire-rated divisions and ensure they are maintained to the original approved specification. This includes paying close attention to cable and pipe penetrations.

The type and thickness of insulation depends on the material it is protecting. For example; steel begins to lose its design margin of safety at temperatures of around 550°C. For aluminium the temperature is much lower at around 150°C. At 275°C aluminium will lose around 50% of its yield strength. Composites soften as temperatures rise, resulting in reduced structural properties for a laminate. The glass transition temperature of the resin affects the amount of insulation required for a composite. Performance of cores & fibres across a range of temperatures also impacts the amount required.

The April 2020 edition of Survey Matters contains the basic principles and examples of data sheets and certificates of compliance for Aluminium - A30, Steel - A30, and Composite - A60 structural fire protection.

Key items a surveyor should verify

Installing protection under approved design and OEM guidelines is the only way to achieve the aims mentioned above. This includes:

- Ensuring only appropriately tested solutions are used.

- The requirements of the performance standards (Fire Test Procedures Code or the High Speed Craft Code) are specific. Products not designed and tested to meet these standards are not acceptable (see below).

- Insulation requirements vary based on type and thickness of the material it is protecting. Requirements also vary depending on the area on the vessel and the time rating of the division.

- Having concise and accurate approved drawings, of the proposed arrangements.

- Verifying that materials and fittings are correctly installed by competent personnel, i.e. as stated in the approval documentation and/or the manufacturer’s instructions. For example, pins are fixed to the substrate correctly. Pins are sufficient in nature as per approval documentation and achieve required returns.

- Verifying that the means of protection are inspected and tested at regular intervals. This includes prompt repair and renewal whenever necessary.

- Checking the certification of the SFP, do not confuse non-combustible products, with those properly tested and certified as part of time rated fire-resisting divisions (structural fire protection).

Examples of unacceptable products

Pink batts are not acceptable. They are combustible above 350°C and are designed for comfort insulation and acoustic use only.

Intumescent paints and similar solutions do not meet the performance requirements for use. They are not approved for use as structural fire protection solutions.

A solution approved for use on steel, is not necessarily suitable for use on aluminium or fibreglass. Even if it is certified for a higher time rating than required.

A solution approved for use in a land-based building is not approved for use on a vessel. The performance criteria are significantly different between vessels and buildings. The environment, firefighter response time and distance to safety or rescue if a fire breaks out differ.

Out of water survey requirements

AMSA has noticed there is some confusion about what items must be surveyed as part of a periodic out of water survey. The confusion stems from the out of water survey items section at the bottom of Table 9 in chapter 4 of SAGM Part 2.

The out of water survey items section is not an exhaustive list of items that must be surveyed as part of a periodic out of water survey. The whole of table 9 must be considered when conducting a periodic out of water survey and any item with a tick next to it must be surveyed.

When you conduct a survey for an OWAT code, ensure all applicable items in Table 9 are examined, verified, tested or trialled, and documented on your reports.

Navigation light requirements

AMSA frequently receives enquiries from vessel owners and operators regarding the navigation light requirements for domestic commercial vessels. During audits we have also noticed that navigational light arrangement plans are commonly omitted, or these details aren’t reflected in the general arrangement plan as part of the initial survey documentation.

Does my vessel need a navigation light arrangement Plan?

For vessels which must comply with Pt. C of COLREGs, AMSA expects that a navigation light arrangement plan, approved by an AMS, is available on board. This plan may contain details regarding the different types of navigation light, minimum range of visibility, horizontal and vertical positioning and spacing of the lights etc.

Alternatively, for smaller vessels, these details can be provided on the general arrangement Plan.

A profile view and table of navigation lights on a ship over 50m is shown below for illustration purposes only (not to scale).

| Item number | Light | Type | SI number | Range | Visibility | Colour |

|---|---|---|---|---|---|---|

| 1 | Fore Masthead Light | -- | -- | 225° | 6nm | White |

| 2 | Aft Masthead Light | -- | -- | 225° | 6nm | White |

| 3 | ------- | -- | -- | -- | -- | -- |

Can a vessel use LED navigation lights?

LED navigation lights can be installed, subject to several conditions listed in IMO resolution MSC.253 (83).

However, AMSA reminds all owners, operators and accredited surveyors that the luminous intensity of LEDs gradually decreases while the electricity consumption remains unchanged. The rate of decrease of luminous intensity depends on the output and temperature of the LEDs.

What are the additional requirements for LED navigation lights?

Marine Order 30 requires navigation lights, navigation light controllers and associated equipment, installed on DCVs after 30 November 2009 to conform to performance standards at least equal to those mentioned in the Annex to IMO Resolution MSC.253(83).

To prevent shortage of luminous intensity of LEDs, the following additional requirements have been specified in IMO Resolution MSC.253 (83):

- An alarm function should be activated to notify the Officer of the Watch that the luminous intensity of the light reduces below the level required by COLREGs;

or

- LEDs should only be used within the lifespan (practical term of validity) specified by the manufacturer to maintain the necessary luminous intensity of LEDs. The lifespan of LEDs should be determined and clearly notified by the manufacturer based on the appropriate test results on the decrease of luminous intensity of the LEDs under various temperature conditions and on the temperature condition of LEDs in the light during operation, taking the appropriate margin into account.

What should an accredited surveyor check regarding LED Navigation Lights?

Accredited surveyors are encouraged to check the following documentation/marking checks in addition to the routine safety and operation checks;

- Valid type approval certificates for reference to IMO Resolution MSC.253 (83) and for special installation instructions.

- Check if the Navigation light controller is included in the type approval certificate and the controller is approved in accordance with MSC. 253 (83).

- Check the LED light or the manufacturer documentation for navigation light expiration dates.

- When completing the AMSA 901, specify LED for Navigation Lights as well as the expiration date.

If expiry dates aren’t specified by the manufacturer, check for alarm functions on the bridge for reduction in luminous intensity of LED Navigation Lights.

Lines plans/hull model requirements

The Surveyor Manual Part 2 Table 2 requires that a lines plan (or electronic 3D hull file) is provided when comprehensive stability criteria is used. This is expanded in NSCV C6C, clause A8.8.4 as part of the information supporting the inclining experiment.

This may elicit concern, as it is a valuable piece of intellectual property. AMSA appreciate that a lines plan represents sensitive proprietary hull design information often built up over many years. It can also represent a significant investment of time to model an existing vessel, providing a competitive advantage.

We understand and appreciate these concerns. AMSA has a comprehensive privacy policy on our website.

The rationale behind the requirement for lines plan data (either in the form of a drawing or a 3D hull model) is to permit audit in accordance with section 45 of the regulations.

Another reason for requiring a lines plan is to aid investigation in the event of an incident linked to the vessel stability. Should stability need to be assessed the provision of hull data allows for this to be undertaken.

Hence, when comprehensive stability is used on a vessel, either a lines plan containing the data listed in Table 2 of SAGM Part 2, or an electronic hull file, such as a Maxsurf hull file or *.iges is required in support of a recommendation for stability approval.

Autonomous vessels in Australia

AMSA has recently seen an increase in the use and application of autonomous vessels in Australia. AMSA has produced guidance material to assist operators of these vessels to comply with the national system. The guidance notice is now available on the AMSA website and helps improve our regulation of emerging technology in Australia.

Guidance Notice – Small uncrewed autonomous vessels

Nitrogen oxide (NOx) emission requirements for marine diesel engines on DCVs

As a part of global measures to reduce harmful nitrogen oxide (NOx) emissions, marine diesel engines with an output above 130kW must now meet NOx emission requirements.

Globally, the shipping industry is reducing NOx emissions by requiring marine diesel engines with a power output of greater than 130kW to comply with NOx emission limits. To confirm an engine is compliant, an Engine international air pollution prevention (EIAPP) certificate and a technical file must be carried on board for each engine.

AMSA has introduced measures that will assist DCV owners and operators comply with the NOx emission requirements. Under Exemption 44, DCV owners and operators can hold specified alternative evidence that demonstrates engines are likely to meet the NOx emission limits.

Read more information about the requirements

The AMSA National Compliance Plan 2021-22 is now available

The National Compliance Plan 2021-22 provides practical guidance and a clear view of what AMSA will be looking for over the coming year to make it easier to comply with the national law.

Focus area 3 in the plan specifically addresses domestic commercial vessels. The importance of safety management systems, incident reporting, fatigue management, and compliance with the marine surveyors’ accreditation guidance manual are priority areas for AMSA’s compliance activities over the coming year.

Focus areas 4 and 5 are also targeted to domestic commercial vessels to increase beacon registration and prevent pollution from ships.

Please familiarise yourself with the priority areas and share this information with your clients as the opportunity arises.

We welcome your feedback

Is there a topic you’d like to see covered in a future edition of Survey Matters? Send an email to DCVSurvey@amsa.gov.au with any suggestions or feedback.

Survey Matter—December 2021

In this edition

- Season's Greetings

- Recent surveyor audit findings

- What is corrective action?

- Condition of tailshaft, survey recommended by Surveyor

- Stability audits – common findings

- Maintaining professional competence

- Marine Safety Incident – POB

- Harmonisation of shaft surveys with renewal surveys

- Initial survey of sister vessels

- Weld defects and NDT examination

- NSCV C6B review project commencing

- We welcome your feedback

Season's Greetings

The AMSA team would like to wish all our readers a Merry Christmas.

Tis the season to be jolly, to prosper, and to carry good tidings of this year into the next. Thank you for your partnership and for our valued relationship with you. May you and your family have a wonderful Christmas and may you experience great success this coming New Year. Merry Christmas to you and your family.

The DCV Applications team remain on deck to process temporary operation approvals lodged between Christmas and the New Year.

Recent surveyor audit findings

Since the last edition AMSA has conducted over 30 Accredited Marine Surveyor Audits, most of which covered several surveys.

Many audits were positive, with findings mainly observations or minor non-conformances, however four major non-conformances were issued.

Two major non-conformances were issued to one surveyor because stability books, substantially not meeting the requirements of the NSCV, had been approved. In one case this resulted in AMSA downgrading the previously issued Certificate of Survey. For the repeated breach, the accredited marine surveyor was issued a $2,664 infringement (fine), for not complying with the conditions of their accreditation.

A major non-conformance was issued because an accredited surveyor had completed and recommended a renewal survey for a class 1 vessel > 12 m, accepting the owner’s declaration for the lightship check (instead of a lightship measurement). The accredited marine surveyor implemented corrective actions to ensure the issue was rectified and ensure it would not occur again. A counselling letter for a breach of conditions of accreditation was issued.

A major non-conformance was issued because the requirements of NSCV C7A had been improperly applied during a survey, this resulted in a Class 2C vessel not being provided with a liferaft.

What is corrective action?

AMSA conducts regular audits of the survey records and recommendations made by Accredited Marine Surveyors (AMS). The purpose of these audits is to monitor the quality of the surveys conducted, ideally promoting, and assisting with continuous improvement.

AMSA categorise findings from audits as follows:

- Observations (these can be positive, neutral, or negative) - these are for the information of the AMS and require no response to be provided to AMSA.

- Minor non-conformances and Major non-conformances – these require a corrective action to be provided to AMSA.

What does a corrective action need to achieve?

A corrective action needs to:

- Correct any immediate issues, if required, to make the problem right; and

- Correct systemic issues (issues in your survey system), to prevent re-occurrence, for example by incorporating:

- lessons learnt; or

- improvements to survey techniques and procedures.

- The substance of the corrective action should be proportionate to the level of the Non-Conformity identified.

Examples

| Non-Conformity | Example of Corrective Action | Good or Bad? |

| Minor Non-Conformity – Form 638 for SHAFT survey does not indicate that a dimensional check was conducted and no supporting documentation supplied in this respect. | “Dimensional check was done; shafts are in good condition.” | Bad - No Immediate or Preventative Corrective Action |

| “Please find attached a revised form supplemented by copies of my field notes. Going forward more attention will be paid to providing the correct information in recommendations for shaft surveys, evidenced by supporting documentation, if required.” | Good – Correct Form supplied with supporting documentation and measures to prevent re-occurrence (lessons learnt). | |

| Major Non-Conformity – Temporary Operations Permit was issued to the vessel following Renewal Survey when major deficiencies remained not rectified. | “I’ve known this operator for years and he is very trustworthy. I had every confidence that he would rectify the items before operating, therefore I issued a Temporary Operations Permit with these items outstanding. There was no risk to safety. Everything has now been repaired and the vessel is in good condition. “ | Bad – No preventative corrective action |

| “I have followed up with the owner who confirms that all of the major deficiencies have now been rectified. I have reviewed Exemption 07 and now better understand the conditions under which I have the delegation to issue a Temporary Operations Permit. I have updated my survey procedures accordingly.” | Good – Immediate corrective Action (follow up) and Preventative Corrective Action (lessons learnt, procedures updated). |

The purpose of the audit process is to assist surveyors to identify areas of improvement in their survey process. AMSA and accredited surveyors must work together to build trust with customers, by improving the professionalism, accuracy and consistency of surveys conducted around Australia.

Condition of tailshaft, survey recommended by Surveyor

During the desktop audit of a periodic shaft survey recommended by an accredited surveyor it became apparent that the surveyor recommended a periodic shaft survey of a water lubricated shaft, in the condition shown below, for a 1C passenger vessel. Despite noticing significant surface corrosion/pitting and excessive wear on the shaft, the accredited marine surveyor recommended the shaft survey without performing adequate tests (e.g.: NDT, dimension/trueness check etc.) to determine the suitability of shaft for the next 5 years. AMSA seeks your view whether you would recommend shaft surveys for this tailshaft without performing any additional checks or remedial action.

Stability audits – common findings

AMSA audits accredited marine surveyors to ensure the correct procedures and protocols set out in the National Law - Marine Surveyors Accreditation Guidance Manual (SAGM) and the Marine Safety (Domestic Commercial Vessel) National Law Regulation 2013 (the regulations) are being implemented.

AMSA has performed over 300 audits related to Stability approvals from accredited marine surveyors (AMS), with the assistance of Transport of New South Wales. Most of the submissions from accredited surveyors were found to be compliant and several positive observations noted. However, some of the audits identified several serious findings and the vessels failed to meet criteria. Below are some of the most common non-conformances identified:

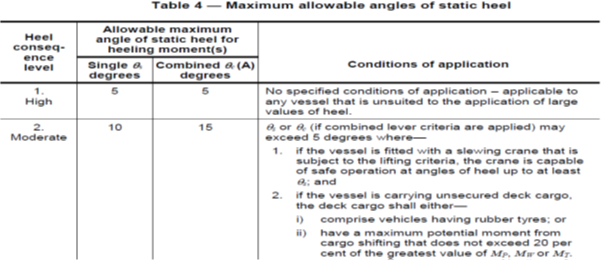

1. Maximum allowable angle of Static Heel

In most cases, the AMS determined the heel consequence of the vessel as low and applied the allowable single and combined angles of static heel as 14 and 18 degrees respectively. However, during the audits, it was noted that several vessels did not meet the conditions of application of low heel consequence level. Several of these vessels failed to meet the comprehensive stability criteria for angle of heel when heel consequence of the vessel was determined as Moderate or High. AMSA encourages AMS approving Stability Booklets to ensure that the conditions of application for appropriate heel consequence level are met for each vessel. These conditions ensure that the vessel has adequate capacity to control the risks as the static heel angle increases. NSCV Part C Section 6 Subsection 6A Ch.3.8 Table-4, cited below, addresses these requirements:

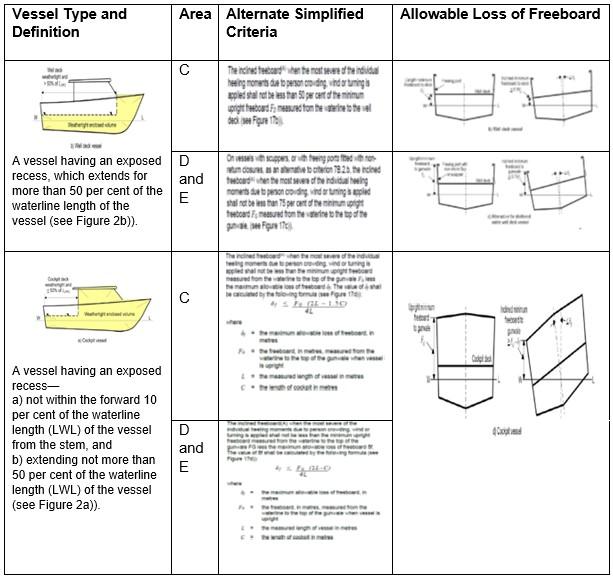

2. Allowable loss of freeboard calculation using alternate simplified criteria.

In several cases, the type of vessel (cockpit vessels and well deck vessels) was identified incorrectly by the surveyor, which leads to application of incorrect simplified stability criteria for calculation of the allowable loss of freeboard. In several cases, it was noted that the accredited surveyors used the allowable loss of freeboard criteria for cockpit vessels, instead of using well deck vessel criteria. AMSA identified, during the audits, that these vessels failed to meet the well deck criteria. Definition of the type of vessel can be found in NSCV Part C Section 6 Subsection 6A Ch.1.7 and Fig-2. The relevant simplified stability criteria for measurement of inclined freeboard can be found in NSCV Part C Section 6 Subsection 6A Ch.7.4.5. We have summarised the definition and requirements in the below table for the ease of reference.

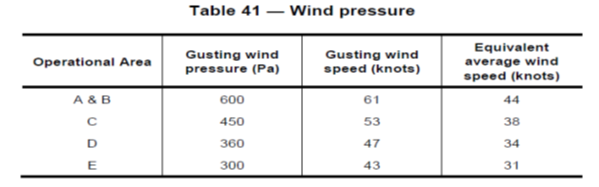

3. Wind pressures in bare poles condition for sailing yachts.

For sailing yachts, surveyors have applied wind speed restrictions for operations during bare poles to satisfy the criteria for wind heeling angles, in some cases. Surveyors should consider not applying a restriction in wind speed, while calculating the wind heeling moments in bare poles condition.

AMSA considers application of a restriction on wind speed as failing the criteria for wind heeling angles for the area of operation. The minimum wind pressure to be used in the wind heeling moment calculation is specified in NSCV Part C Section 6 Subsection 6A Annex B 3.1 Table 41, as cited below:

Maintaining professional competence

Section 28 of the Marine Safety (Domestic Commercial Vessel) National Law Regulation 2013 (the regulations) requires an accredited marine surveyor to maintain professional competence in the categories of surveying in which they are accredited.

AMSA expects an accredited surveyor to:

1. Maintain their professional competence in marine surveying.

As a guide AMSA generally expects every accredited surveyor to spend at least 45 hours over a 3-year period maintaining professional competence on items directly related to the role of a surveyor. The table below should be used as a guide.

2. Fulfill the Continuous Professional Development (CPD) requirements of their professional association, to maintain membership.

This varies from association to association and the scope can be broad. Associations would normally consider crediting professional competence items mentioned above against their CPD requirements. Associations typically require 105-150 hours of CPD over a 3-year period.

If an accredited surveyor takes a break from surveying, AMSA does not generally expect them to maintain their professional competence during this period. However, if an accredited surveyor re-commences surveying, AMSA expects them to be able to demonstrate they have spent a suitable amount of time fulfilling the requirements above and may request evidence that their professional competence is up to date.

If an accredited surveyor takes a break from surveying, AMSA does not generally expect them to maintain their professional competence during this period. However, if an accredited surveyor re-commences surveying, AMSA expects them to be able to demonstrate they have spent a suitable amount of time fulfilling the requirements above and may request evidence that their professional competence is up to date.

| Activity | Maximum number of hours to count per 3-year period | Examples |

| Keeping up to date with changes to the National Law and AMSA processes | 20 Hours (mandatory) | This includes the reading of ‘AMSA Survey Matters’, familiarisation with changes to SAGM, Marine Orders and Exemptions. |

| Workshops and technical meetings | 20 Hours | Technical meetings, including AMSA workshops and relevant professional association meetings. |

| Courses | 25 Hours | Tertiary or short courses in Law, Naval Architecture, Marine Engineering, Electrical Engineering, Fire, Risk Management, Working at Heights, Confined Space Entry. |

| Practical training | 15 Hours | Training with a more experienced AMS or an AMS with a different skill set. |

| Private study which extends relevant knowledge and skills. | 5 Hours | Private study includes the reading of books, journals, transactions, technical content on the internet etc. |

| Any other structured activities that meet the purpose maintaining professional competence. | Unlimited, but to be balanced with some other professional competence activities listed above. |

Marine Safety Incident – POB

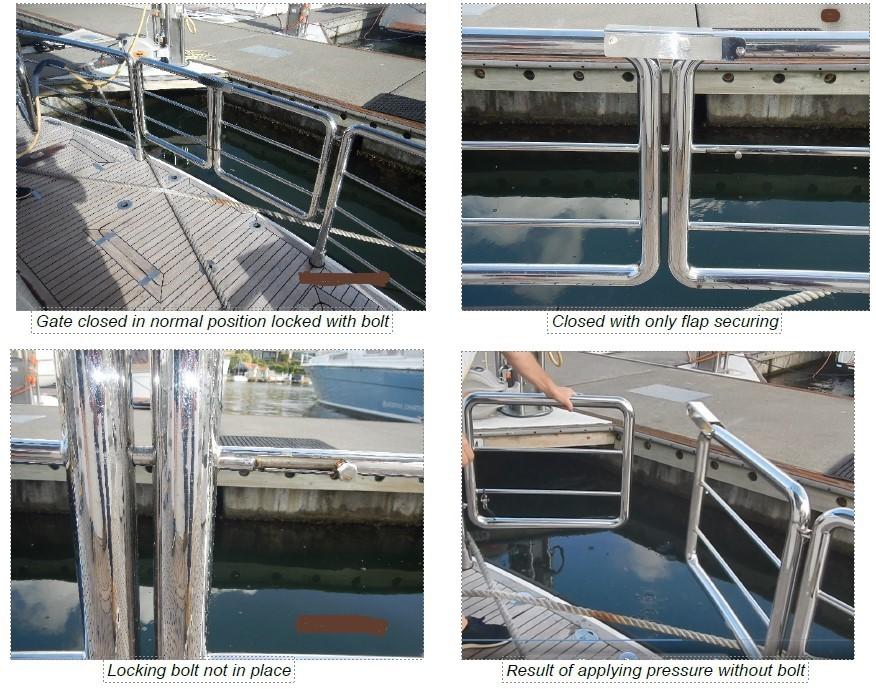

A private charter cruise vessel had an incident when a guest with a toddler walking from aft deck to the swim platform fell overboard. The master had seen the guest with the toddler a few seconds earlier on the CCTV but no one saw them fall. A few seconds later the master noticed that the double gate was wide open and he could not see passengers on the swim platform. The persons overboard were spotted about 80-100m astern and before they could be reached, there were screams and yells from the toddler’s mother who jumped into the water to rescue. The POB were retrieved successfully and bought on board – shaken but no injuries.

Why this happened?

- The guest is assumed to have leant against the gate which opened under the pressure of his body weight.

- The double gate had not been properly secured shut with the locking bolt at some stage prior to departure.

- The gate was only held shut by a “flap” cover that did not fully prevent opening under pressure.

- The gate can open both inwards and outwards with no ‘stop’ preventer either way.

AMSA has conducted a review of the vessel’s safety management system and identified deficiencies relating to risk assessments and passenger verification procedure. The operator has engaged a fabricator to redesign gates and to prevent them from opening outwards.

Safe design is a better control than administrative measures such as the safety management system

It is requested that surveyors inspect the opening and gates in bulwarks and railings for securing devices and bring any safety concerns to the attention of the owner and Master.

Harmonisation of shaft surveys with renewal surveys

Sometimes owners voluntarily draw shafts outside a vessel’s renewal survey window, perhaps if there is an issue with the bearings/sealing arrangements or if the shafts require renewal.

The SAGM requires that shafts be withdrawn and a SHAFT Survey conducted as part of a renewal survey. If a shaft has been previously withdrawn, just outside the renewal survey window, owners can obviously be reluctant to do this again.

Therefore, if a SHAFT survey is done outside the Renewal Survey window the best option (as the vessel will be out of the water) is to conduct a full Renewal Survey early to set the vessel up for the next 5 year cycle.

If this is not possible, owners have the option to apply for a Specific Exemption (SPEX) to allow the likes of a new shaft to be exempt from the requirement to be withdrawn at the next Renewal Survey. Such exemptions would only be granted in exceptional circumstances. Factors considered would be the time between shaft surveys being requested, the age of the shaft, the number of shafts the vessel has, envisaged running hours, the type of shaft material used, the type of bearing lubrication, whether the vessel is left in the water for prolonged periods without the shaft turning, duration of repair facility (slip) availability etc...

Previous State Authority practices of allowing shafts to be withdrawn at periodic out of water surveys are no longer considered.

Initial survey of sister vessels

For AMSA to issue a certificate of survey, an application must be supported by the required survey reports and recommendations.

For the initial survey of a sister vessel, clause 3.9.5 of Part 2 of SAGM provides that, in lieu of full plan approval, the basis vessels approved plans are able to be submitted, and they need to be accompanied by a statement from an accredited marine surveyor with category ‘a’ (plan approval) accreditation (as per clause 3.9.1) as well as a lightship comparison report of the basis and sister vessel.

Depending on the type of sister vessel, the accompanying statement would need to confirm the basis and sister vessels’ service categories, crew, special personnel and passenger numbers, and maximum speeds.

Construction and commissioning phases of initial survey are to be conducted as per any other new vessel construction, in accordance with Part 2 of SAGM.

If you do not currently hold copies of the basis vessels plans and/or stability documentation, you may be able to request copies of the basis vessels records, however intellectual property considerations may apply.

Please see the AMSA website for instructions on how to request vessel records.

Weld defects and NDT examination

Weld defects may have serious consequences if not identified and properly repaired. Different types of weld defects cause different effects on the ships structure.

Cracks, lack of fusion and incomplete joint penetration can create notch effects. Discontinuities such porosity and slag inclusions amplify stresses by reducing the weld area.

Cracks – are the most serious type of welding defect because of their tendency to propagate under certain levels of stresses. They are the primary cause of structural failure. Cracks act as stress concentrators and are not acceptable for ship hull welds, regardless of their size. They must be repaired immediately.

Lack of fusion – is a failure of the welding process, fusion failed to occur between the base metal and the weld metal, caused by improper welding techniques, preparation of the material for welding, incorrect joint design.

Lack of penetration – This is a root condition in which the weld bead does not penetrate the entire thickness of the base plate or when two opposing beads do not interpenetrate. This will cause weld failure if the weld is subjected to tension or bending stresses.

Undercut is a groove melted into the base metal adjacent to the weld toe or weld root and left unfilled by weld metal. Concavity is a weld discontinuity in which the maximum distance from the face of a concave weld perpendicular to a line joining the weld toes is insufficient.

Inclusions are entrapped foreign solid material, such as slag, flux, or oxide.

Porosity occurs because of weld metal contamination. Gas is entrapped in solidifying weld metal. It is generally spherical but may also be elongated. Excessive hydrogen is one of the main causes of porosity and moisture is a major source of hydrogen.

Overlap - is an excess of weld metal covering the parent metal but not fused to it. Incorrect welding procedures, inappropriate selection of welding material, insufficient travel speed are some of the typical causes of overlap. This is one of the serious welding defects on ships and should be avoided.

Misalignment occurs in plates in the perpendicular direction to the plate surface and weld axis.

The non destructive test (NDT) methods used for detection of weld surface imperfections are visual testing, liquid penetrant testing and magnetic particle testing.

Ultrasonic testing and radiographic testing are NDT methods used for weld internal imperfections.

The acceptance criteria, defined by recognised organization or Australian Standards, can be used for the assessment of the results of different NDT methods.

For more information on welding inspection refer to instruction to surveyors DCV-ITS08.

NSCV C6B review project commencing

AMSA has commenced a review of NSCV C6B (Stability and buoyancy after flooding). The project seeks to make amendments to NSCV C6B based on issues and feedback supplied by accredited marine surveyors.

Specifically, the project will:

- review and validate the flotation and foam requirements of Annex C, D and F

- develop a new alternative simplified level flotation annex for low complexity vessels

- review and validate the raking damaged requirements for inflated collar vessels

- review the number of watertight doors per hull and the type of door

- develop guidance to assist with implementation and compliance

AMSA will be developing a Technical Advisory Panel (TAP) for this project. Interested industry stakeholders should complete the TAP nomination form available on the We welcome your feedback

Is there a topic you’d like to see covered in a future edition of Survey Matters? Send an email to DCVSurvey@amsa.gov.au with any suggestions or feedback.

Survey Matters—March 2022

In this edition

- Correct and incorrect use of conditions

- Inclining experiment methods

- NSCV C7A safety equipment requirements

- LPG Installation case study

- B extended operations

- N & C flag requirements

- Testing and servicing of fire suppression equipment

- Have your say: NSCV C1 consultation

- National Law review

- Construction barge safety campaign

- Exemption 6 has been updated

Correct and incorrect use of conditions

Conditions are used to impose additional requirements on duty holders. They cannot be used to avoid compliance with a requirement of the law. This is only permitted by exemption.

Correct use of conditions

Conditions can be used to require a duty holder to do additional things. For example, AMSA could impose a condition requiring a master to check engine oil each morning (if we believed it was necessary and correct to do so).

Checking the oil is not a “standard” requirement of the law. Marine Order 503 and the standards do not explicitly require the master to check the engine oil each morning. Nonetheless, if a condition is imposed on the certificate, the master would be required to meet this condition (see section 38 of the National Law).

Incorrect use of conditions

A condition on a certificate cannot be used to “overrule” or contradict the requirements and conditions set out in the National Law.

For example, the National Law Marine Orders may require a vessel to carry a life raft. A condition cannot be used to overrule this requirement. A condition such as "life raft not required to be onboard provided master only operates in D waters” would not have the desired effect. It is not an exemption.

Examples of correct conditions

- Opening between engine room and steering compartment at Frame 37 to be closed watertight during 1D operations

- Recommended Condition: Vessel operations limited to within 30NM radius of safe haven and able to return to safe haven from any point in 2 hours. Reason: Vessel fitted with single anchoring system.

Examples of incorrect conditions

- Vessel to operate in 1D until in service life raft returned to vessel

- Vessel to carry life-saving equipment (Life jackets and life buoys) appropriate to the number of crew onboard.

- Fuel tank to be removed and inspected at or before next renewal survey in September 2023

If you come across a vessel that does not comply with the law, for example because the life raft is not onboard or because they have not completed the surveys required by the Law; then your duties as a surveyor are to communicate the deficiencies to the owner on an AMSA 586, and work with the owner to ensure the issue is rectified. If the owner needs to operate with exemptions, flexibility is provided through Exemption 6 and Exemption 7. Where appropriate, the owner may also apply for a specific exemption.

Inclining experiment methods

The National Law permits the use of equivalent and alternate solutions for meeting the standards. This may permit use of alternate incline methods, on a case-by-case basis. AMSA has for example allowed some smaller vessels to apply the ASTM F3052-14 and SNAME Technical Bulletin 9-1 methods for air inclinings.

An article entitled Scaling the Wall: Inclining Experiment Analysis on Vessels with Chines, Hull Discontinuities or Asymmetry was recently published by Richard Dunworth, Naval Architect, Department of Defence, in the November 2021 issue of The Australian Naval Architect.

This article introduces and discusses the merits of a KN based inclining method that may deliver more accurate inclining results for asymmetrical hull forms and vessels where waterplane area changes during inclining, such as RIB’s.

Surveyors who wish to apply this method for vessels, that are difficult to incline in a traditional manner, or any other non-conventional method, such as air inclining, can apply for an equivalent means of compliance using AMSA form 649.

If you are considering applying for an equivalent solution, please ensure you are familiar with the method you intend to apply and can demonstrate the method will be at least as effective as the solution it replaces. For example, with the KN method:

- KN values must be available and accurate for small intervals of heel. 5-degree intervals such as traditionally used in a stability assessment are not sufficient.

- Procedures must ensure the vessel is free to heel and will not hang on lines, touch bottom or similar. Noting the method does not appear to have a mechanism to identify these types of issues, particularly because results may be non-linear as waterplane area changes.

NSCV C7A safety equipment requirements

Marine Order 503 requires all vessels to comply with NSCV C7A for safety equipment. This means new, existing and transitional vessels.

The latest amendment of NSCV C7A commenced on 1 January 2018 and includes Annex I which outlines the phased arrangements for existing vessels to meet with regards to updating safety equipment. Annex I includes timeframes starting from the next periodic or renewal survey after 1 January 2018, during which time the update in specific equipment must be carried out. There are also deadline dates should no periodic or renewal surveys occur beforehand.

At the time of writing this article, all deadline dates have now passed, except for the requirements for stowage of liferafts (within 12 months of the next out of water survey or 1 January 2023). The following is a summary of some of the major items that surveyors must be looking for during periodic and renewal surveys. The list below is not exhaustive, and AMSA recommends surveyors familiarise themselves with all the requirements of NSCV C7A if they haven’t done so already. NSCV C7 Equipment guidance notices are also available on the AMSA website.

IMPORTANT: Only lifesaving equipment that falls under NSCV C7A requires updating. Anchoring, navigation, and communication equipment are not required to be updated to the NSCV standards on existing vessels.

| NSCV C7A Clause | Description | Requirement |

| 4.3.1.3 | Signage | Stowage locations for safety equipment shall be marked. The signage shall indicate the type of equipment and the quantity if more than one unit is stowed there. The signage should use symbols conforming to IMO Res A.760(18). |

| 4.5.3 | Liferaft stowage | For Class 1 vessels only - Means shall be provided to ensure that the stowage positions of liferafts, the launching devices (where fixed launching devices are used), and the areas of water into which the liferafts will be deployed shall be sufficiently illuminated |

| 4.5.4 | Liferaft signage | Posters, signs, or operating instructions shall be provided on, or in the vicinity of liferafts and their launching controls and shall— a) illustrate the purpose of controls and the procedures for operating the appliance and give relevant instructions or warnings; and b) be easily seen under emergency lighting conditions. NOTE: Symbols used should conform to IMO Resolution A.760(18) Symbols Related to Life-saving Appliances and Arrangements. |

| 4.6.4 | Illumination of dinghy stowage and launching areas | Means shall be provided to ensure that the stowage positions of dinghies and the areas of water into which the dinghies will be deployed shall be sufficiently illuminated |

| 4.7.3 | Illumination of buoyant appliance stowage areas | Means shall be provided to ensure that the stowage positions of buoyant appliances are sufficiently illuminated. |

| 4.8.2 | Lifebuoy stowage | A lifebuoy shall be stowed so that it— b) is readily accessible to crew or passengers; and |

| 4.9.2 | Lifejacket stowage | Lifejackets shall be stowed in clearly marked, easily located, and readily accessible stowage areas. The stowage areas shall be dry and protected from weather and excessive heat. |

| 4.9.3 | Lifejacket signage | Written and pictorial instructions to be provided adjacent to lifejacket stowage area |

| 4.10.1 | Pyrotechnic stowage | Pyrotechnic and smoke signals shall be stowed in a buoyant watertight container, fitted with a handle or lanyard. The container shall be clearly and permanently marked as to its contents. On Class 1 and Class 2 vessels the container shall be readily accessible to the crew. On Class 3 vessels the container shall be mounted in a float free position and be readily accessible. |

| 5.3, tables 2, 3 and 4 | Dinghy replacement | Except for certain Class 3C vessels, a dinghy is not permitted to be used as an alternative to an inflatable liferaft. For Class 3C vessels <25m, a dinghy may continue to be used as an alternative to an inflatable liferaft provided it meets the requirements of NSCV C7A Annex C within 12 months from next periodic or renewal survey, or within 24 months from 1 January 2018, whichever occurs first. Where the existing dinghy being used in place of a liferaft is due for replacement, it shall be replaced by an inflatable liferaft. |

| 5.3 table 2 | Open reversible liferafts | Class 1 vessels that carry buoyant appliances (Carley Floats) and operate in areas where it may be unsafe for persons to be immersed in water (e.g., Water temperatures below 15 deg or dangerous wildlife) must replace their Carley floats with Open Reversible Liferafts (ORLs). Vessels that opt to carry buoyant appliances must have a risk assessment included in their SMS that justifies the use of buoyant appliances in lieu of ORLs. |

| 5.3 table 2 | Buoyant appliances and lifebuoys | A vessel shall carry the kind and quantity of buoyant appliances and lifebuoys mentioned in Table 2 |

| 5.3, tables 2, 3 and 4 | Number of lifejackets | A vessel must carry lifejackets for 100% complement. In particular, 1E vessels that were permitted to carry fewer lifejackets under the USL Code must now carry 100% complement. |

| F2.6 | Painter on Carley floats | A buoyant appliance shall be fitted with a painter that shall be of sufficient length to allow deployment of the buoyant appliance from its maximum possible height and have a breaking strength of 10 kN. |

| H3.2 | Medical equipment and supplies | Equipment supplies shall be in accordance with H3.2. NOTE: This includes the kind, quantity, scale and standard of medical equipment and supplies. NOTE: GES 2015/01 may also apply for C, D and E water vessels where the owner/master has done a risk assessment. |

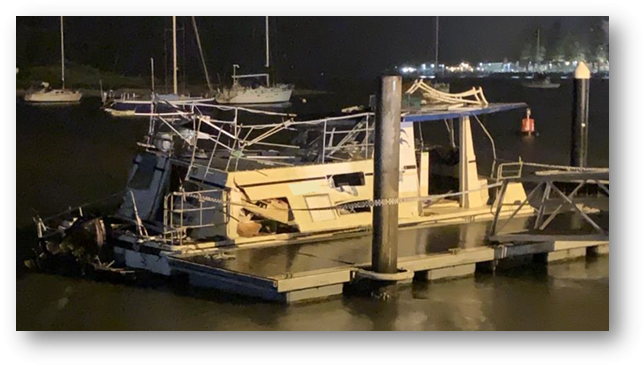

LPG Installation case study

In June last year an explosion occurred on board a houseboat when the owner attempted to light a gas-powered stove via a piezo ignition switch. The explosion caused catastrophic damage to the vessel structure & fittings and both people on board were hospitalised with burn related injuries.

AMSA inspected the 9.9m vessel following the incident and found that major structural damage had occurred to the superstructure, windows, doors, hatches, compartments, fittings and fixtures. The join of fibreglass between the hull and superstructure was cracked and had delaminated away from the hull in the area surrounding the lower cabin. The carpet and curtains were singed, whilst the galley and dining area floor had delaminated. The dining table had also been flipped upside down.

The vessel had a fixed gas system installed which was certified to supply a cooktop, refrigerator, and instantaneous hot water system. Two 8.5kg LPG cylinders were located on the upper deck during inspection, one was connected to the fixed gas system.

Two gas connections were located in the galley during inspection. One supplied the gas cooktop while the other was not connected to an appliance. There was no gas fuelled refrigerator on the vessel. The hot water system was connected to one of the LPG cylinders on the upper deck and was not supplied by the fixed gas system. A valve and connection linked to the fixed gas system was also located externally aft of the vessel, but it was not connected to a hot water system.

Following the incident AMSA engaged a gasfitter to inspect the fixed gas system. At the time of inspection, the gasfitter found the system was not compliant with the requirements of Gas Supply (Consumer Safety) Regulation 2012 because:

- Gas appliances as indicated on the compliance plate were not installed

- Where appliances weren’t fitted, the connection points were not sufficiently capped to prevent a gas leak

- A gas detector was not on board

Following a pressure test of the system, the unused gas connection in the galley was found to be leaking when tested in the off position. The connection and valve located externally was also found to be leaking. The components of the external connection were made from a half-inch kinko nut and olive compression fitting. These fittings are manufactured for use in water copper pipe systems and are not compliant with gas system requirements.

The gasfitters report stated that it is likely the LPG leak from the disconnected gas fridge isolation valve in the galley would have contributed to the presence and accumulation of explosive vapour within the vessel.

AMSA concluded that:

- Propane gas was most likely the cause of a flammable gas air mixture within the vessel

- A faulty gas isolation valve leaking through an open outlet within the kitchen cabinetry was likely the source of uncontrolled gas escape

- The source of ignition was almost certain to be the piezo ignition switch on the gas cooktop which was operated by the owner in the moment before the explosion

AMSA reminds surveyors of the periodic survey requirements listed in Table 9 of SAGM Part 2. Surveyors should look for signs of alterations, modifications, deterioration and disconnections when inspecting the condition of LPG systems. Verification of compliance certificates/plates for installed gas equipment is also required under Table 9. In accordance with section 6 of the National Law, gas systems must also comply with the applicable state or territory gas safety regulator requirements. A licensed gasfitter should inspect the system if there are any concerns.

B extended operations

NSCV Part B defines B extended operations as:

...for use beyond 200 nm from the baseline of any of the following but in waters to the outer limit of the EEZ:

(I) the Australian mainland;

(ii) the Tasmanian mainland;

(iii) a recognized island

Additionally, the definitions of 1B extended, 2B extended and 3B extended state that the vessel must comply with the NSCV requirements for use in operational area unlimited domestic operations.

The phrase operational area unlimited domestic operations is of crucial importance as this is the definition used for Operational Area Category A.

What are the implications?

A vessel that is used for operations in B extended area is required to meet the NSCV requirements for class 1A, 2A or 3A vessels as applicable where specific B extended requirements are not defined.

The NSCV contains several significant changes between Operational Area Category B and Operational Area Category A.

A summary of the changes that may need to be addressed is given in the table below (current for NSCV as at March 2022)

| NSCV Part | Application for Operational Area B extended vessels |

| C1 | The accommodation level must be AL72+ Some changes apply in Chapter 6 requirements may apply |

| C3 | Vessel must comply with robust operation and LR SSC G5 service area restriction, this may require reassessment of the vessels structure. |

| C4 | Some class 1 vessels will have an increase in fire risk category: e.g., Class 1 vessels with 13 – 36 berthed passengers and Class 1 vessels with 37 – 200 day passengers will increase from FRCIII to FRCIV |

| C5A | Class 1 vessels must comply with Marine Order MO12 irrespective of length. Class 2 vessels greater than 35m and 500GT must comply with MO12 Bilge pump requirements change. |

| C5B | The capacity of emergency power supply in class 2 and 3 vessels increases from 2 to 12 hours |

| C5C | No changes |

| C5D | No changes |

| C6A | 5B stability criteria is not applicable to catamarans All vessels must apply the severe wind and weather criteria in Annex H |

| C6B | Class 1 vessels must meet SOLAS Chapter II-1 |

| C6C | No changes |

| C7A | Vessels must comply with Marine Order MO25 and Marine Order MO11 |

| C7B | Vessels must comply with Marine Order MO27 |

| C7C | Vessels >24m must comply with Marine Order MO27 |

| C7D | No changes |

These changes are applicable for new vessels. Some, if not all, will apply to transitional vessels. It is strongly recommended that a gap analysis is carried out early in the process to identify any areas that require upgrading when any vessel is considering operating in operational area B extended.

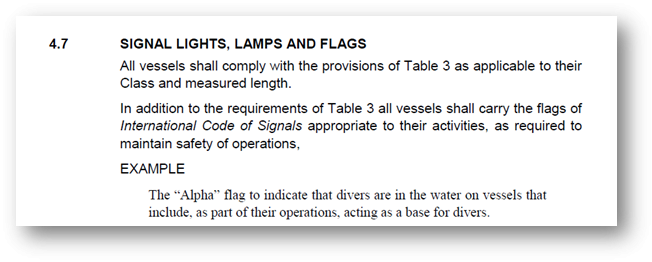

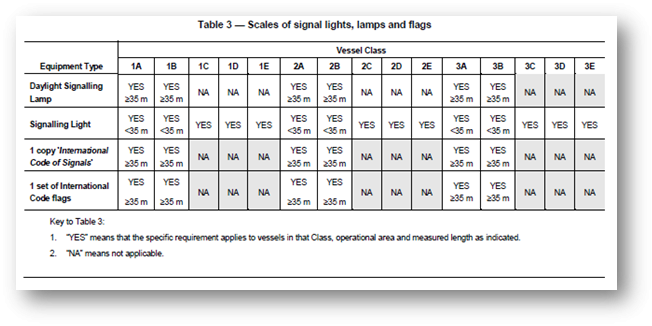

N & C flag requirements

Recently AMSA has become aware of some confusion surrounding the requirements for the provision of signal flags under the NSCV.

The requirement for signal flags is enlivened under NSCV C7B section 4.7 and table 3 (see below)

l

l

There is no requirement in table 3 to carry a full set of international code flags for vessels in operational areas C, D and E. Section 4.7 only requires carriage of the specific flags which are appropriate to maintain safe operations (which is upon the operator to decide based on their operational risk assessments in the vessel SMS). The example given being the “A” flag for diving operations or the “H” flag for pilotage operations

It is often thought that the “N” & “C” flags are required as part of section 4.7. There is no direct requirement under the NSCV for the carriage of these flags. The USL code Section 13 did require the “N” & “C” flags for vessels in service category class 1C and 2C and all vessels in service areas A & B. The NSCV does not require the carriage of the “N” & “C” flags for vessels in C, D or E service areas.

Testing and servicing of fire suppression equipment

Written by the Fire Protection Industry (ODS & SGG) Board

The Fire Protection Industry (ODS & SGG) Board (FPIB) is encouraging domestic commercial vessel owners and operators to prioritise the regular testing and servicing of fixed fire suppression equipment, irrespective of when a vessel is due to be surveyed under Marine Order 503.

For owners and operators of vessels in low or medium survey frequency it might seem convenient or cost-effective to coordinate testing or servicing of fire suppression equipment when the vessel is due to be surveyed.

However, these owners and operators should not take unnecessary risks by putting off routine testing and servicing of fixed fire suppression systems and/or portable extinguishers as these are safety-critical devices and it is vital they function properly in the event of a fire to preserve both life and property.

While some vessel owners and operators may view this maintenance as an unnecessary expense because they consider the possibility of a fire to be low, a lack of testing and servicing can lead to much higher costs down the track.

Owners and operators may not be aware that the chemical agent inside the fire suppression system on their vessel has a higher chance of unintentionally discharging the longer it goes untested or serviced. In some cases, this inaction can result in the fire suppression system or portable extinguisher not operating at all.

In terms of costs, a gas cylinder installed in a fire suppression system on an average size marine vessel typically contains around 13 kilograms of scheduled extinguishing agent, costing the vessel owner roughly $2,500. If this system discharges due to a lack of adequate maintenance over time, not only does the vessel owner have to pay for a replacement cylinder with new chemical agent, but they must also pay an installation cost – which should be carried out by a licensed fire technician. In simple terms, overhauling an entire fire suppression system far outweighs the cost of having an existing system tested or serviced.

Vessel owners and operators should aim to have their fixed fire suppression system serviced every 12 months, and portable extinguishers every 6 months. These are the recommended timeframes as stated in Australian Standard 1851 – Routine Service of Fire Protection Systems and Equipment.

Vessel owners and operators should also have their fixed fire suppression systems and portable extinguishers undergo pressure testing every five years to ensure there are no leaks to the gas cylinder, and that it will work correctly if required.

Owners and operators should be aware that when gas cylinders become low on pressure, they have a higher chance of discharging chemicals into the atmosphere which can cause depletion to the earth’s ozone layer or contribute to global warming depending on the substance.

The FPIB would encourage all accredited marine surveyors to take a proactive approach in educating vessel owners and operators around the importance of testing and servicing fire suppression equipment on a regular basis. This might be as simple as a two-minute conversation at the conclusion of a survey.

We would recommend that if you are a surveyor and have relationships with owners or operators of vessels belonging to the low or medium risk class, that you please raise the testing and servicing guidelines outlined above. Doing so could save lives, as well as save the owner or operator thousands of dollars if they have to replace a fire suppression system unnecessarily.

Without even realising it, marine vessel owners and operators can actively help to preserve the natural environment by reducing the risk of their fire suppression system equipment unintentionally discharging.

For any concerns or queries, please reach out via ozone@fpib.com.au

Have your say: NSCV C1 consultation

AMSA is now inviting feedback on proposed changes to NSCV Part C1, which contains standards for wheelhouse visibility, escape, accommodation, and personal safety.

The proposed changes include:

- meeting disability accessibility standards

- improved standards for escape routes, escape lighting and signage

- clarified definitions of ‘special working decks’ and ‘working decks’

- further risk management associated with a person falling overboard and the recovery of persons overboard, by improving technology requirements and inclusion of a ‘no-climb’ zone

- a minor relaxation of when toilet and ship sanitation facilities must be fitted

- improved ventilation requirements

- improved safety requirements for pilot vessels

- changes to gangway requirements

- alignment of some requirements with already adopted national and international legislation and standards.

It is proposed that the amended NSCV Part C1 will only apply to newly constructed vessels and vessels that undergo modifications to the arrangement, accommodation, and personal safety aspects of the vessel.

Following consultation, we propose that the new standard will come into effect on 1 January 2023 with a transition period of two years.

Consultation is open until 24 April 2022.

Learn more and submit your feedback

National Law review

The Australian government has commissioned an independent review of Australia’s Domestic Commercial Vessel safety legislation and associated costs and charging arrangements.

The review will be undertaken by an independent expert panel, supported by the Department of Infrastructure, Transport, Regional Development and Communications. AMSA is a stakeholder in this review.

The review will be conducted in two phases, with the first to focus on the National Law framework (Phase 1) and the second to consider national system delivery costs and future funding options (Phase 2).

Submissions for phase 1 of the review are being accepted until 30 March 2022. You can visit the Department of Infrastructure, Transport, Regional Development and Communications ‘have your say’ webpage to make a submission. You can also email submissions to dcvsafetyreview@infratsructure.gov.au.

Discussion of the National Law review has also been added as an agenda topic for the upcoming surveyor workshops. This is so we can hear your view, but note this is not an AMSA review, you need to make comment directly to the Department.

Construction barge safety campaign

AMSA has launched a new safety campaign focusing on the importance of regularly reviewing risks to protect lives on construction barges.

A dedicated campaign website is now available to support owners, operators and individual workers and we encourage you to share the campaign information and advice with your clients.

A series of free workshops covering risk assessment will also be delivered by AMSA, in partnership with state and territory WHS agencies.

The first workshop will be presented in partnership with WorkSafe NSW on 29 March in Drummoyne, Sydney. More workshops in other locations will be announced.

Please recommend this workshop to your clients in the greater Sydney area. For more information and to register online click here.

Exemption 6 has been updated

AMSA has recently updated Exemption 6 Marine Safety (Periodic survey, equipment certification, compass adjustment and liferaft servicing). The new amendments provide greater flexibility for operators when liferafts are being serviced, repaired, or replaced.

DCVs can now operate when a liferaft is out of action, provided there are enough liferafts to accommodate all persons onboard the voyage.

Read more about the update here.

Survey Matters – November 2022

In this edition

- Audits and application assessments

- Certificate of survey refusal reasons

- Understanding the surveys required notice letter

- How to apply for a periodic survey extension

- Navigation light supply

- Novel vessel policy

- Relevant reading

Audits and application assessments

AMSA audits accredited marine surveyors to ensure the processes set out in the National Law – Marine Surveyors Accreditation Guidance Manual (SAGM), Marine Order 503 and the Marine Safety (Domestic Commercial Vessel) National Law Regulation 2013 (the Regulations) are followed correctly.

For example:

- The assessment of certificate of survey applications identified major non-conformances in the plan and commissioning survey for two passenger vessels. These included:

- Required plans not submitted.

- Plans approved but indicated that parts of the vessels were non-compliant with the relevant standards.

- No evidence of required inspections being conducted throughout the survey process.

- Inability to demonstrate that the vessels complied with the NSCV stability or fire safety requirements.

Both survey applications were refused and AMSA formed the view that the surveyor had contravened sections 32 and 36 of the Regulations.

Following a show cause process, the surveyor had conditions placed on categories a, g, h, and k of their accreditation. The conditions limit the type and complexity of vessels for which the surveyor can now undertake initial survey. The surveyor is prevented from undertaking surveys on more complex vessels that require greater proficiency in passive and active fire protection measures; watertight and weathertight standards; and propulsion and engineering systems.

Another surveyor had their accreditation varied following complaints raised by regional AMSA staff. Desktop audits of various survey activities identified that the surveyor often failed to submit survey recommendations to AMSA until several months after the completion of the surveys.

Incident investigations undertaken on some of these vessels identified further non-conformances and AMSA formed the view the surveyor had contravened sections 32, 33 and 36 of the regulations.

Following a show cause process, the surveyor had conditions imposed on their periodic survey accreditation. The conditions require the surveyor to provide AMSA with additional evidence of certain survey items, along with their survey reports, within 10 days of the survey date.

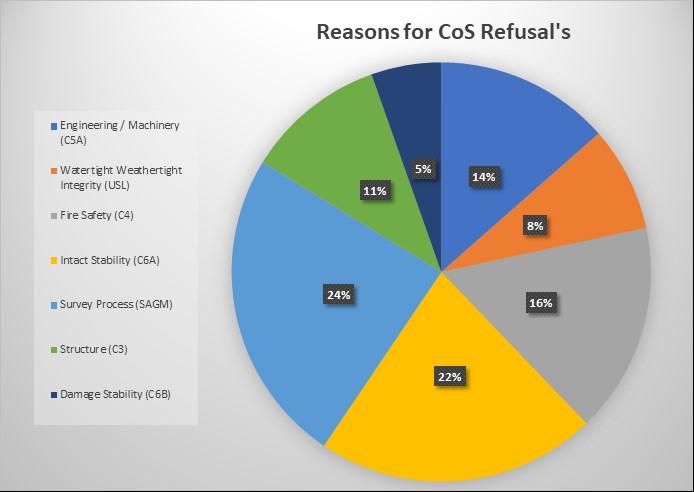

Certificate of survey refusal reasons

AMSA approves around 97% of Certificate of Survey (CoS) applications. This means around 3% of CoS applications are refused, which is an undesirable outcome that can occur for several reasons.

Reasons for CoS refusals

Below is a breakdown of why initial CoS applications were refused in 2021-2022.

- Engineering/Machinery (C5A): 14%

- Watertight weathertight integrity (USL): 8%

- Fire safety (C4): 16%

- Intact astability (C6A): 22%

- Survey process (SAGM): 24%

- Structure (C3): 11%

- Damage stability (C6B): 5%

SAGM specifies survey requirements for vessels by prescribing a consistent process for accredited marine surveyors (AMS) to follow. The National Law requires an AMS to apply the process set out within SAGM to ensure nationally consistent survey outcomes and safe vessels.

Failure to follow the SAGM process can result in the refusal of an application. In fact, this is the most frequent reason for refusal of an initial CoS application. Moreover, failure to implement SAGM removes a layer of assurance which can result in non-compliant vessels.

Compliant survey vessels are the result of three overlapping parties working together to produce quality outcomes:

- designers,

- builders, and

- surveyors.

Designers and builders have general safety duties to ensure a vessel is designed, constructed, and subjected to tests and trials as required, to guarantee it meets the relevant standards. Survey assurance is a critical control to validate the quality systems within the design and construction process and independently verify a vessel meets the standards expected by the Australian public.

It is not a surveyor’s sole responsibility to ensure a vessel complies with the applicable standards. Rather, surveyors ensure a designer and builder’s quality systems are being implemented and document the applied process. Surveyors are critically important and responsible for third party assurance of the design and construction process, on behalf of AMSA.

When AMSA identifies non-conformances, we prefer to work collaboratively with the surveyors. AMSA identifies opportunities for improvement in the survey process and assists an AMS to implement corrective actions. This ensures the same non-compliance does not reoccur on future vessels. AMSA does this primarily in two ways:

- by providing an opportunity for additional information to be provided before we decide an application

- through our formal audit program.

These interactions with AMSA are opportunities for surveyors to correct an immediate issue and improve their survey process to avoid repetition. The result of improved processes is a higher standard of surveying, a rise in the quality of the vessels built, and a reduction in AMSA intervention.

Surveyors are subject to conditions of accreditation and a failure to conduct surveys in accordance with an applicable standard is a breach of these conditions. This may result in AMSA taking compliance action against a surveyor, such as formal warnings, infringements, variation, suspension, or revocation of accreditation.

Understanding the surveys required notice letter

A recent update in MARS now allows AMSA to modify the survey activities listed in the Surveys Required Notice Letter prior to it being sent to the applicant.

This update was implemented following feedback that letters were generic and contained survey activities that weren’t required for an application, for example where a vessel has undergone modification. This change has been well received.

However, AMSA has also received applications for new certificates of survey where the full extent of modifications weren’t included. In these instances, the Surveys Required Notice Letter generated without all of the required survey activities being listed.

This has resulted in submissions that do not cover all the survey activities necessary to meet the requirements of Marine Order 503 and/or Marine Order 507 for the issue of certificate(s). This has delayed the issue of certificates until additional surveys were undertaken and the required submissions were assessed.

The excerpt below from the Surveys Required Notice Letter addresses the issue of additional surveys:

Will any other surveys be required for my application?

The survey activity codes listed above have been generated based on AMSA's understanding of the facts and circumstances presented in your application.

However, the surveys necessary for your vessel to meet the requirements of Marine Order 503 and/ or Marine Order 507 and be granted a certificate(s) may differ from the survey activity codes above.

You should seek advice from your surveyor(s) to determine if additional surveys are required for your vessel, particularly if your vessel has been modified. Please have your surveyor contact dcvapplications@amsa.gov.au if additional activity codes are required.

Surveyors may also mark a code as "not required" if, in accordance with the above Marine Orders and the National Law— Marine Surveyors Accreditation Guidance Manual 2014 (the SAGM), a survey listed above is not required.

Note: Failure to complete the surveys required by the above Marine Order(s) and the SAGM may result in delay or refusal of your application.

Accredited marine surveyors are reminded to address such situations with the applicant, conduct the required surveys and make the appropriate submissions.

How to apply for a periodic survey extension

Marine Order 503 allows for periodic surveys to be conducted within the three months before or after the due date. A vessel can continue to be operated without seeking any extensions during this six-month period.

- Example – if a vessel is due for periodic survey on 1st October, the vessel can be surveyed between 1st July and 1st January.

If the survey can’t be completed within the six-month window provided by Marine Order 503, an extension can be requested as follows:

Exemption 6 – this exemption can only be used to apply for an extension for up to 90 days after the period provided by Marine Order 503.

- Example – A vessel’s six-month window runs from 1st July until 1st January – exemption 6 can only be used to apply for an extension until 1st April.

Exemption 7 - this exemption can be used to apply for an extension for a periodic survey by using the ‘another temporary use’ option (Division 2). This would allow for an application to be made outside the timeframes provided for in both Marine Order 503 and Exemption 6.